Welding cables are dangerous if their size is incorrect. They can overheat and burn the insulation layer, leading to electrical shocks and fires. Sizing a cable size is not straightforward.

It can be difficult for even experienced welders. So, we created this guide to help navigate through nuances and terminology that confuse even experienced people.

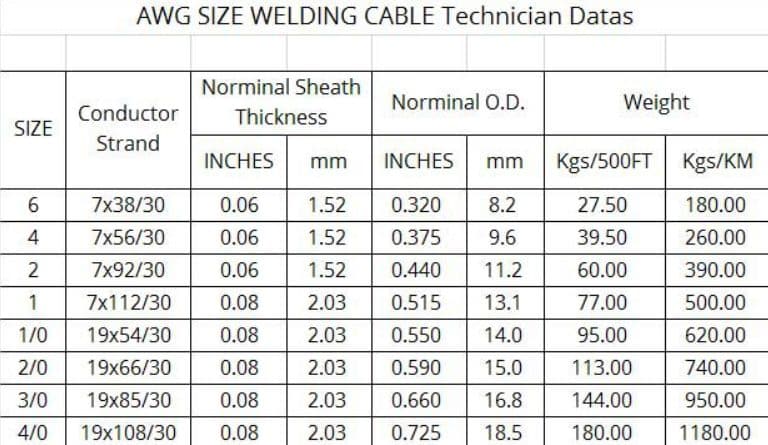

We also created a helpful chart to quickly find the right cable size based on your welding setup parameters.

What Is A Welding Cable?

Welding cables are made of fabric and connect the ground clamp, which holds the electrode holder with the power source. Welding leads are essential for connecting contact to your welding machine.

The main characteristic of welding cables is durability and flexibility, as they must resist cuts, wear, and insulation damage. The cables also need to be able to flex and bend easily.

Cable Core – Copper Or Aluminum

Higher cable strand counts mean more vital cables. For the best flexibility, choose a higher strand count by perusing sites such as CableCordSupply.

Copper is a better conductor than aluminum. Therefore, welding cables need to be thicker for copper-core leads than aluminum-core ones. However, aluminum is lighter and less expensive than copper.

Cable Insulation – EPDM, Neoprene, Or PVC

Cables are usually insulated with rubber or plastic, such as neoprene. These materials are durable and better at preventing damaging cuts and insulation failures.

PVC is better for weatherproofing but less flexible than other alternative materials. However, it is preferable if you plan to work in harsh environments or use rough surfaces. EPDM and neoprene are more appropriate if you weld in typical conditions.

What Size Welding Cable Do I Need?

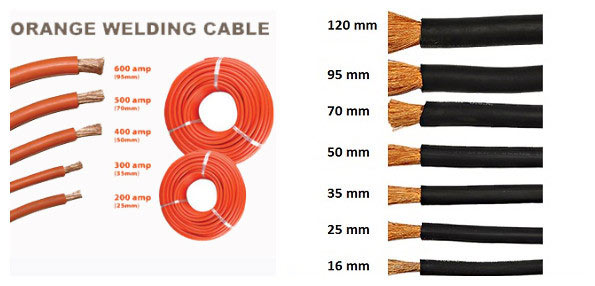

For welding cable, the size is determined by the maximum amperage output of the welding machine and the maximum duty cycle. The current type does not factor into cable size considerations.

The length of the cable is not what determines the size of the cable – you need to consider everything. The length of the cable is only one part of the circuit, so it matches up with everything else.

Cable Ampacity

Cables carry electrical current. When a cable conducts too much amperage, it can overheat and need replacement. Cables also generate heat when carrying amperage and must be rated high enough to ward off danger.

One way of calculating the ampacity of a cable ignores additional factors. The capacity of a cable decreases as the length of the cable increases.

This happens because the longer the cable is, the higher its resistance, which increases the operating temperature. If it gets too hot enough, it can cause damage to its insulation.

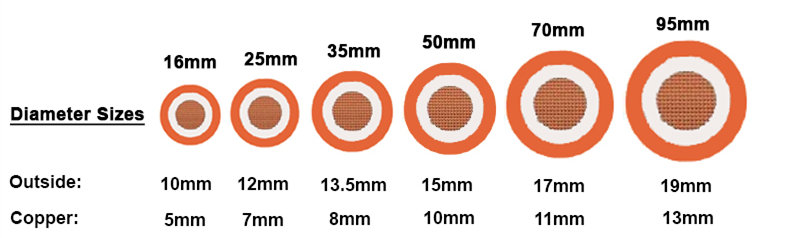

So, as welding cable diameter increases, ampacity rating rises. The resistance of the electrical current flow lessens if the cable’s cross-section is larger.

With decreased resistance, it is easier for the electric current to flow through the cable with less heating up inside.

Duty Cycle

Every welder is rated for an operating duty cycle. The rating notes the portion of a 10-minute interval that they can weld at a specified amperage before resting for the remainder of the time.

For example, a 40% duty cycle at 200A means that the power source can output 200 amps for four minutes before resting for six minutes.

When using high power for prolonged periods, the cable is subject to wearing out more quickly. It’s not as durable and needs to have a beefier design.

Welding Cable Size Chart

Thin and long welding cables cannot carry high currents because of high resistance. This leads to short-circuiting, electrical shocks, or fires. You are likely to contact the wire as you work, which also poses a danger.

With a cable sizing chart, you can find the appropriate wire gauge for your situation. These charts simplify the process, but there are more complex calculations that need to be followed.

Our Video Guide for Welding Cable Size Chart

Wires come in multiple gauges; the smaller the gauge, the larger the cable. For example, if you have AWG 5 wire and use that wire for high power circuits, it helps to get as small of a gauge as possible.

The AWG rating system is often misunderstood. For example, a size of 0 is not classified as 0/0 but rather 1/0. This is because 1 has a double-digit while 1/0 has only one. A triple zero wire may be called AWG 3/0, but technically, it would be AWG 2/0 since there are two zeroes in the rating.

Be extremely careful to avoid committing a classic beginner’s mistake. If you look at the chart below, it is easy to determine that you need an “AWG 3/0” cable, but mistakenly purchase an “AWG 3”. The consequences of this mistake are probably very serious.

This cable is six sizes smaller than the AWG 3 and thus could not handle the data rates of the AWG 3/0 rated cable. When placing an order, make sure that you check carefully to ensure you have the right AWG-rated cable.

Wrapping It

In order for a welding cable to be adequate for your specific setup, it must have an appropriate diameter. Cable sizes are dictated by many factors including the cable length, the amperage, the machine’s duty cycle, and the cable’s insulation rating.

If the cable diameter is larger (e.g., the AWG rating is smaller), then the cable can transport a higher amperage over a longer distance and at a much higher duty cycle.

You should always choose a cable that is one size larger than the one you need if you are ever in doubt.

A cable’s rating is not always 100% accurate. For example, they are usually rated at a temperature of 40 degrees Celsius.

Whenever you weld in an area with a temperature above a certain level, you should use slightly thicker cables. Hence, if you are in a position to afford a larger diameter, it would always make sense to go for it.