Do you want to know how hot a plasma cutter gets? Since heat is the most effective method of cutting metal, the system requires an extremely hot temperature. It is possible to cut 200 inches of material per minute using plasma cutter.

16 Models

Considered

110 Hours of Research

25 Experts Interviewed

380 Reviews Analyzed

Mechanics and scientists are trying to improve the technology for increasing heat. So far, they have achieved traction of more than 200 inches per minute from less than 35 inches per minute. Using plasma, we anticipate that this is only the beginning.

Grapes are even being used to make it in microwaves by some people. You can watch it here.

Related Article : BEST WELDING HELMET FOR MIG

What is Plasma?

Have you ever wondered what the fourth state of matter is? It is plasma, after gases, solids, and liquids. From solid to liquid, from gas to plasma, the matter goes through various states. It is the temperature at which each stage reaches that makes the difference.

According to temperature, molecules in the first three states become closer in solids, move apart in gases, or even float apart in a liquid.

During the separation process, plasma goes one step further by separating the electrons from the molecules. The electrical force created by this process links together all of the molecules, unlike a gas.

Plasma forms when electrons separate from one another through this intense electrical energy that forms, which holds them together. With a plasma cutter, this fierce heat is harnessed to cut through metal.

Related Article: BEST BUDGET WELDING HELMET UNDER $100

Best Plasma Cutter of 2023 – My Top Picks

- Non-Touch Pilot Arc Plasma Cutter

- Safe And At Low Cost:

- The Compatible Consumables Sets

- Easy operation

- Nominal breaking capacity is ½”

- Precision cut quality.

- High quality of grooving

- Drag cutting technology.

- Built in Air Compressor

- Cuts faster than oxy fuel

- Smaller heat-affected zone for less warping

- No gas pressure settings for flame tuning needed

Components of a Plasma System

There are three main components in a plasma system, as summarized below:

Power Supply

Supercharging and heating the gas in the system is done by utilizing this source of power. D.C. voltage ranging between 200 and 400 VDC is converted from A.C. line voltage by the power supply.

The Arc Starting Console

During a plasma torch’s operation, the circuit generates about 5000 VACS, which creates the spark that causes the plasma arc.

Plasma Torch

With this torch, you can get proper alignment and cooling of the ingredients inside. An electrode, a swirl ring, and a nozzle are the main components necessary for creating plasma arcs.

Related Article : Best Welding Helmet for Beginners

How Plasma Cutting Works

Using plasma as a cutting method, heat is generated. Rather than cutting metal mechanically, this process melts it using heat.

There is always a constant mechanic to the system. Gases like nitrogen or compressed air are used in plasma cutters. Plasma is formed through the ionisation of these gases.

By contacting the electrode, the compressed gases ionise to create greater pressure. Plasma flows toward the cutting head as the pressure increases.

Creating a plasma stream is the result of the cutting tip constricting the flow. After this, the workpiece is subjected to it. Through the cutting table, plasma is connected to the ground because it is electrically conductive.

A plasma arc’s high temperature causes the metal to melt as it contacts the arc. Additionally, the fast-moving gases blow the molten metal away.

Related Reads : Best TIG Welder

How Hot Does a Plasma Cutter Get?

As the transitions between states of matter increase, their increments also increase. Water, for instance, converts from a solid to a liquid at just 2°F and from a liquid to a gas at 212°F. In the plasma form, the number increments from 2 to 210 increase further by over 10,000. In plasma cutters, temperatures can reach 40,000°F or 22,000°C.

You can hold this material in your hands, and it’s insanely hot. Many plasma cutters are handheld devices without guards and operate via hand control instead of automated systems.

Larger plasma cutters with computerized systems are equipped with heavy-duty safety features and guards. The price here is under $300, and anyone can buy them.

Although it can be frightening to think that anyone could be operating one of these high-tech machines, I enjoy using them. A plasma cutter is a perfect tool for cutting through nearly any solid sheet of metal.

Related Reads :BEST EVERLAST TIG WELDER

What Does the Future Hold for Plasma Cutting?

Some scientists have measured plasma reaching temperatures approaching 10 trillion degrees Fahrenheit, which is the melting point of a metal plate when exposed to high-end plasma cutters.

This shows the potential of plasma technology, although people are unlikely to use this heat to cut metals. We have the opportunity to harness this phenomenal state of matter in extraordinary ways.

Plasma cutters have the disadvantage of leaving dross, or metal slag, on the cut corners due to their melting process. As opposed to lasers and water-based cutting machines, laser and water-based cutting machines leave a clean-cut, meaning that almost no finishing is required after they have been used.

Related Reads :Best TIG Welder For Aluminum

Lasers and water cutters would produce clean cuts like those in the workshops of many welders. This cutter type is significantly more expensive, does not have removable ranges, and can cut a material between three and 100 times slower than the plasma cutter.

Despite their use by many manufacturers, they are out of place in the typical workshop due to their qualities.

Plasma cutters will surely be in demand with the appearance of lasers and water cutters in engineering, but the future of these technologies will surely rise in this field.

Their effectiveness will be unmatched by the other machines appearing if they can produce smoother cuts at the same or even faster rate.

Related Reads :Best TIG Welders Under 1000$

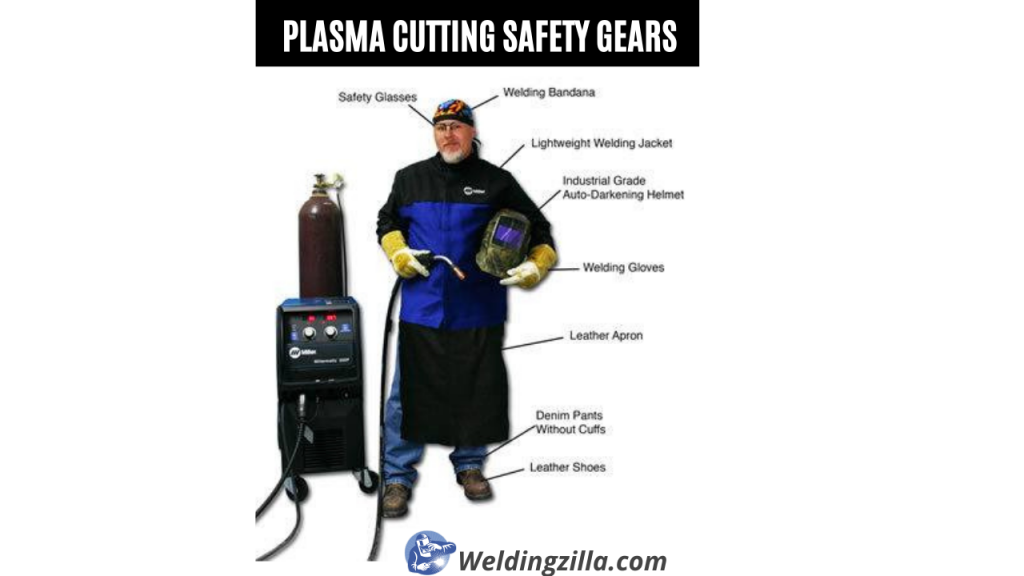

Plasma Cutting Safety Measures

In addition to the high voltage electric power and flammable gas used in plasma cutting, there are also other hazards to be aware of.

- The process generates heat and spark, so there is a need for caution.

- The plasma cutting arc at the initial process of piercing metal generates hot metal and sparks.

- Workpieces and cutting torch get heated up, causing them to burn.

- Safety glasses fitted with side shields are required because the flashes are too bright for the eyes.

- It is not safe for you to wear your clothes. Sparks from flying sparks can burn them, and a flame-resistant shirt is a solution.

- Matches or lighters will become dangerous if you keep them in your pocket while using a plasma cutter. Despite the gloves and skin, the heat from the plasma cutter is so strong that it can cut through them.

Related Reads : Best Trolling Motor Battery

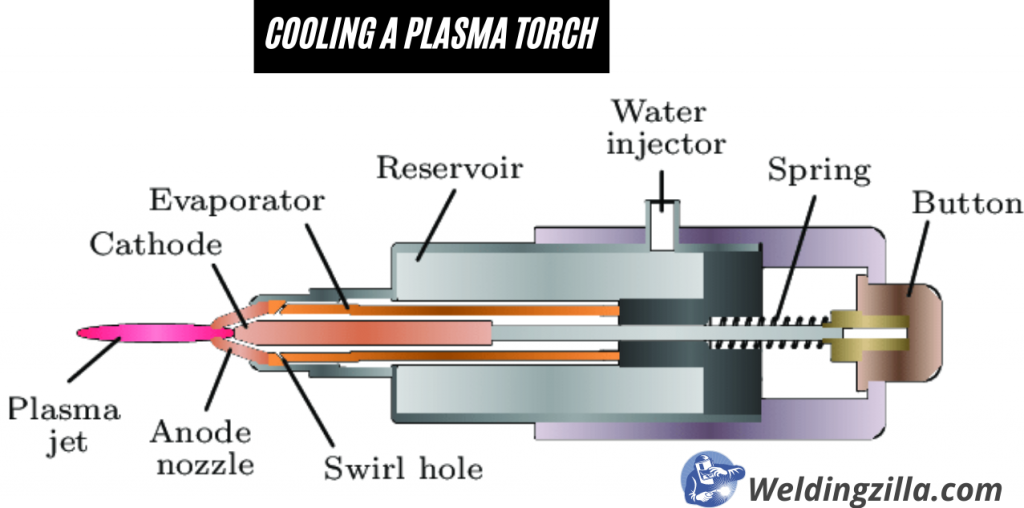

Cooling a plasma torch

- While in operation, a plasma torch gets too hot and must be cooled to prevent the melting of the electrodes and nozzles

- Plasma torches can be damaged by high temperatures, which a coolant can alleviate.

- The electrode’s back is open to the coolant, which is released through the narrow opening there. Heat is then carried away as quickly as possible by it.

- The liquid returns to the torch’s body after cooling the electrode. It then passes through another outlet to cool the nozzle.

- By swirling the coolant outside the nozzle, the nozzle will last longer.

- The process is repeated as long as the plasma cutter is in operation.

- It leaves the burner and returns to the cooler as long as the machine is on.

Related Reads : Best TIG Welding Gloves

Is A Plasma Cutter Hotter Than The Earth’s Core?

Let’s think about something closer, something in our locality, our solar system. The center of the earth is probably the hottest place on the planet. There is a lot of iron being pressed under high pressure to create extremely hot conditions at the earth’s core, and this is why things are so hot down there.

What is the temperature of the earth’s center? The temperature is about 10,800 degrees Fahrenheit. So, plasma arcs will achieve flames that burn at temperatures four times greater than the earth’s center!

Now that we have reassured you about how much heat is generated by a plasma system, we hope you are more comfortable.

How hot is a plasma cutter? Is it hot than the sun?

It may not be hotter than the sun, but a plasma cutter generates enough heat to generate 40,000 degrees. Plasma cutters generate such high levels of heat that it is vital to use them carefully.

Even though the amount of heat is controlled by the metal itself, a coolant can tone down the excessive heat generated by a plasma cutter.

There is a tremendous amount of variability when it comes to measuring sun temperature. The plasma cutter uses a flame that has a temperature roughly 4.5 times higher than the sun’s surface.

As you go farther into the sun, the temperature rises quite dramatically, and by the time you reach the really hot center, it is about 27,000,000 degrees.

Despite what you’ve heard, your plasma cutter will not get that hot. It can only match the temperatures of the upper layers before it becomes hotter than the sun itself.

How Can You Modify the Heat Of The Plasma?

Matter exists in four states, including plasma. Molecular constituents of plasma possess much more energy than gases (the third state of importance).

Essentially, you are watching a thunderstorm play out in miniature when electrons hit the neutron core and bounce off of the molecules that make it up, creating intense levels of energy.

Possibly, you’re starting to think that plasma cutters are too hazardous for your work environment, so you’ll stick with other tools instead. The temperature can be easily reduced to something a little less hot.

Our focus has been on the maximum temperature of the plasma jet, but you are not required to increase the power source and send the sun’s force to the metals.

Don’t forget that, with a plasma cutter, many materials can be cut with other cutters – plasma cutters are meant for specialist jobs where no other cutter will do.

In addition, we would like to stress that if you feel that plasma cutters are too dangerous for you, you should not use them. Get help from someone who knows how to plasma cut, or find a different method of cutting your material.

Related Reads : Best MIG Welders Under $300 To Buy In – Reviews & Buyer’s Guide

Selecting Plasma Cutting Machines – A Beginners Guide

When buying welding equipment, there are several factors to consider.

It’s also important to consider the thickness of the material you’ll often be cutting. The ideal machine for you is a higher amp machine if you plan to cut thicker material generally.

The first step is to determine what speed is optimal. What would be more convenient for you, a quick or a slow cut? Depending on the thickness of the metal, check the manufacturer’s recommendations for its cutting speeds.

Thinner materials are best cut with plasma cutters with lower amps. Plasma cutters in this category provide better control and cleaner cuts.

Take a moment to think about how plasma cutters work. Computers and office equipment can be affected by plasma cutters that conduct electricity via a pilot arc at high frequency.

Related Reads : Best MIG Welders Under $300 To Buy – Reviews & Buyer’s Guide

Choosing a cutting machine that employs the lift arc method is prudent if you’re working in such an environment. The electrodes and nozzles are D.C. negative. You do not have to worry about damage to your office equipment when you use this type of plasma cutting machine.

Buying welding machines requires that you consider welding safety gear. As you are being exposed to high voltage, the nozzle protects you. Accidents can be caused by any mistake, no matter how slight.

Make sure the machine you get has a safety sensor that ensures the nozzle can’t be removed while it’s still on.

Related Reads : How to Change The Battery in Welding Helmet – 7 Easy Steps

Frequently Asked Questions [F.A.Q]

![Frequently Asked Questions [F.A.Q]](https://weldingzilla.com/wp-content/uploads/2021/05/image-71.png)

Can A Plasma Cutter Cut Rock?

Yes, but not all rocks conduct electricity. A plasma arc would die if it did not contact the rock, and the rock would remain without any marks on it. The circuit voltage would be reduced to zero when most forms of rock conduct electricity. Plasma can cut conductive materials, so this is not an issue when cutting sheet metal because it is a conductor.

What Gas Do You Need for A Plasma Cutter?

A plasma cutter can generate flames by pushing a pilot arc through a constricted hole filled with gas. There are many types of gases that can be used, including air, oxygen, argon, and nitrogen. Plasma-cutting machines automatically control the plasma gas flow.

Related Reads : Best Welder for Home Use (MIG, TIG, Stick) – Welding Zilla

How Hot Does A Plasma Cutter Get?

It is possible to reach 45,000 degrees Celsius in a plasma arc. To avoid raising your electricity bill very high, make sure you are staying away from using plasma cutters as much as possible.

Is Lava A Plasma?

The answer is no. Lava is not plasma. Even though the lava is very hot, it is molten rock ejected by a volcano. That makes it a liquid. At the same time, a plasma is even hotter than the most energetic gas.

Related Reads : Best Flux Core Welder – Top Picks, Reviews & Guide

What Is Lightning Made Of Plasma?

A plasma column can form in the center of a lightning bolt when it discharges. An electron and ion flow through a gaseous medium creates a temporary plasma state and extremely high voltage.

Conclusion

Indeed, plasma cutters are capable of extremely high temperatures. The sun’s surface can be compared to it, while the core of the earth is hotter!

If the pilot arc is sparked correctly and you have the proper safety equipment, you will be able to cut through virtually any kind of material without any problem.

A plasma cutter is an invaluable tool in many shops because of this. You should not operate a metal cutter or begin cutting metal if you feel insecure or do not feel safe – instead, ask for help and have someone else do it for you.