- Will do 1/4″ aluminum and 3/8″ mild stee and 110/220 volts and is capable of welding 7018, 6013

- Advanced Inverter Technology with PWM (Pulse Width Modulation) Using IGBT technology

- Quality TIG welding on aluminum, stainless or steel and precise welding of thinner-gauge materials

- MIG machine uses 0.30, flux core wire.

- Up to 140 Amp output that allows you to weld mild steel up to 1/4 in plate

- Lightweight 19 lbs. easily carried to any Do-It-Yourself, Maintenance, Repair,

- Metal Fabrication and Hobbyist project

- All metal case, Built to take the day to day. Big enough to handle 2 and 10 pound rolls of wire

The saying goes that half the battle lies in having the right tool for the job. If you have ever been frustrated by a welder that doesn’t cut it or seems not suited for your needs, you know that there is some truth in this statement.

Do you need a Best Welder for Home Use that can be used with a standard 110V outlet if your power lines are 220V?

How do you know the type of power necessary for your new welding equipment? Should you install a higher amperage breaker?

What will an additional cost be? If you’re starting to sweat, don’t! We’ve streamlined the normally complex process of buying a new welder by comparing the most important features of eight of the Best Welders for Home Use you can buy right now.

Best Welders for Home Use – Top Picks

45 Models Considered

176 Hours of Research

28 Experts Interviewed

400 Reviews Analyzed

Best Welders for Home Use – Reviews

Here is a list of the eight Best Welders for Home Use.

1. Hobart Handler 140 – Best Home MIG Welder

A 140-amp MIG welder is the strongest MIG welder you can plug into a standard electrical socket, so it would be hard to beat it unless you’re planning a major electrical remodel of your home. This would clearly dramatically increase the cost of your welding hobby.

This welding machine offers five voltage settings and a wire feed range of 40-700 IPM, giving you complete control over your weld depth. The amperage setting allows you to adjust the weld speed and amperage as you see fit.

A welder capable of welding up to 14″ mild steel, this model is more than adequate for hobbyists and engineers. The five-year warranty shows Hobart’s confidence in the product. Its only flaw is its rather heavier than usual weight.

While this portable welder is still portable at 57 pounds, you’ll probably need a cart if you’re welding a great deal on the road.

- Easy to adjust

- Easily connects to any standard electrical outlet

- Warranty of five years

- The welder can weld mild steel up to 14.”

- It weighs 57 pounds.

Related Article : BEST WELDING HELMET FOR MIG

2. AHP AlphaTIG – Best Home TIG/Stick Welder

The AlphaTIG 200X, on the other hand, provides versatility and combines TIG and stick welding into one unit. It eliminates the need to purchase a second unit to accommodate two different welding needs.

Because the AlphaTIG can be operated with 110 and 220 volts of electricity, it may be easily installed in most shops. Its ability to weld up to 14” aluminum and 1/8″ steel means this welding machine can be used for a wide range of projects.

With the best three-year warranty, it provides peace of mind that AHP stands behind their product. The only downside is that it is considerably heavy at 69 pounds. You will need to set it on a wheeled cart to move it around your house.

- Provides TIG and stick welding

- 1/8″ mild steel and 1/4″ aluminum

- The warranty is for three years.

- Suitable for both 110 and 220 volts

- Sixty-nine pounds is quite heavy

Related Article : BEST WELDING HELMET -TOP PICKS AND REVIEWS

3. Forney 261 MIG Welder – Best Value

Having a budget is one of the most important factors in making a tool purchase decision for DIY welding hobbyists. If you’re worried about having money left over for materials after purchasing the welder, we recommend the Forney Easy Weld 261.

A mild steel welder for mild steel up to 14″ thick features an infinite voltage and wire feed speed control so that you can precisely adjust the settings for every weld, every time.

With only 19 pounds of weight, the easy weld machine plugs into a standard 110v outlet and delivers amperages from 32 to 140. With only 110v power, it is extremely portable and can be used wherever you are.

Moreover, it boasts a small footprint, as not take up your valuable workspace when it’s not in use and includes a one-year warranty.

- Control of current and voltage at any time

- Connects to standard outlets.

- Miniature footprints

- There is no weight limit

- The warranty is only for one year.

Related Article : BEST BUDGET WELDING HELMET UNDER $100

4. Lincoln Electric K2278-1 Home Welder

MIG welder that can be stored in any cabinet. However, despite its small size, it weighs 45 pounds, so it appears even lighter than it is. It plugs into any standard household outlet.

Due to its limited output range, this Lincoln welder can only weld mild steel up to 1/8″ thick. This may be sufficient for gentle hobby work, but you should consider a unit with higher capabilities if you’re building anything structural.

- The price is modest.

- A very small area.

- The unit is powered by 110-volt electricity.

- The amperage range is only 35-88

- 1/8″ mild steel is the maximum thickness that can be welded

- Although it is small, it weighs 45 pounds.

Related Article : Best Welding Helmet for Beginners

5. Lotos LTPDC2000D Plasma & TIG Welder

It includes both a TIG welding and stick welding unit. It also consists of a plasma cutter set! Combine all three into one portable unit, and you’ve got a surprisingly useful set of tools!

A plasma cutter can cut through metals up to 1″ thick, and the TIG and stick welding options supply amps between 15-200. Unfortunately, this model doesn’t have a foot pedal for TIG welding, and it is not suited to TIG welding aluminum.

However, it must be run with a double 50AMP circuit breaker and thicker wiring than what’s probably in your walls now. Although it can be powered by 110v or 220v electricity, it is not meant to run on a standard home 20AMP circuit.

At 42 pounds, it’s not the heaviest, but it’s not light either. You’ll need 220v to power it; not everyone can do that.

- With one machine, you can weld with TIG and stick

- It comes with a plasma cutter

- A double 50AMP to 220v breaker is required.

- TIG welding aluminum is impossible.

- TIG welding does not require a foot pedal.

Related Reads : Best TIG Welder

6. Reboot Stick Welder

The Reboot stick welder weighs just 13 pounds and features an included adapter that adapts it to 110v or 220v power. Its 120 amp output on 110V and 160 amp output on 220V is the most efficient of all our recommended welders here.

There are reports that the converter malfunctions sometimes, resulting in the welder only running for a few seconds before stopping.

This unit has the advantage of being reasonably priced, but the build quality does not match the price tag. The product feels cheap, and it has sometimes been reported to fail. While it offers a great deal of value, you can find more affordable offerings that are more reliable.

- This is a very portable device.

- Affordable

- Poorly constructed

- It is known that the power converter malfunctions.

Related Reads :Best Plasma Cutters ()

7. SUNGOLDPOWER MIG 150A Welder

The SUNGOLDPOWER MIG 150A welder might be the right choice for you if you’re really on a budget and just need the cheapest setup. This welder even includes welding wire and a mask at one of the lowest price points on our list.

Although this welder is not especially inexpensive, the old cliche “you get what you pay for” absolutely rings true here. Don’t expect it to be as easy to use or quickly set up as welders at the top of the list.

Unfortunately, this cheap item doesn’t run perfectly. Although designed to run on 110v power, you’ll need a 40- or 50-amp circuit breaker. The wire feed mechanism sometimes breaks, making it impossible to feed the electrode.

- It’s super cheap.

- The breaker must be at least 40- or 50-amps

- It is common for wire feed mechanisms to break.

Related Reads :BEST EVERLAST TIG WELDER

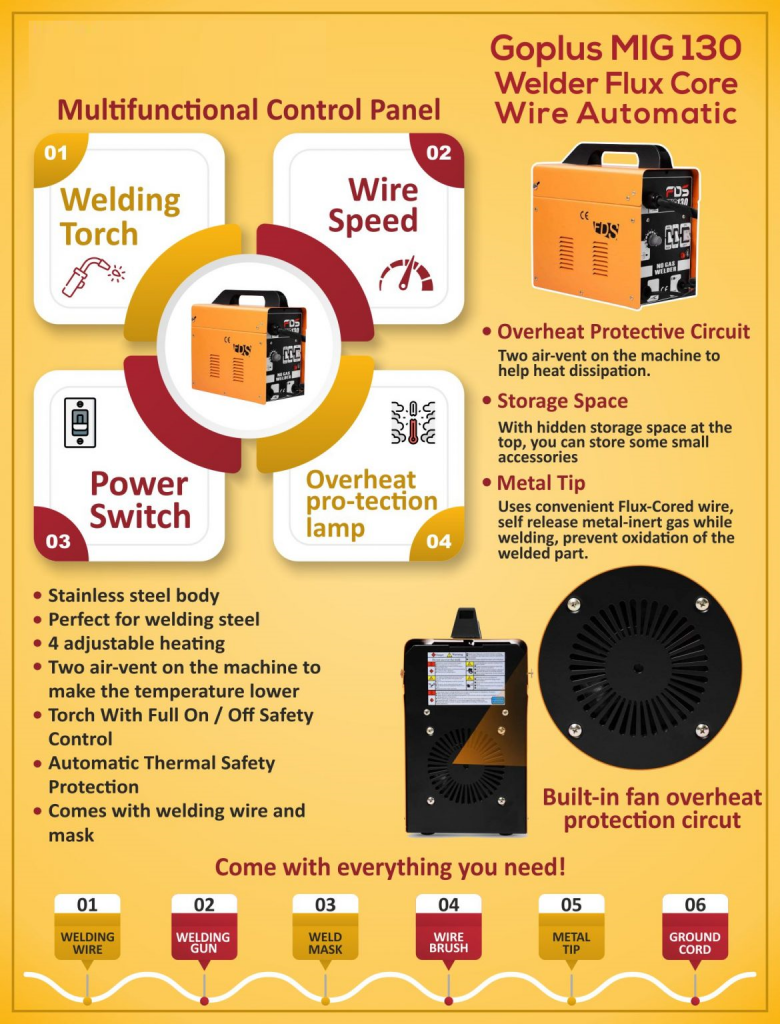

8. Goplus MIG130 Welder for Home Use

It comes with a mask, wire, brush, and a starter kit that makes it a good choice for beginning welders. The MIG welder weighs 35 pounds and has four welding speeds, with ten levels of wire feeding speeds.

However, it is a flux core wire welder, and it does not offer proper MIG welding, as its wire feed is inconsistent, making it extremely difficult to get a clean weld bead. If you are just getting started, this will only make learning welding frustrating.

In addition to frequently arriving damaged, this product has a three-month warranty. Overall, this machine doesn’t inspire much confidence. There are better options available for the price.

- Affordable

- A MIG welder, not a real one.

- Often arrive damaged.

- Unstable wire feed speed

- Three-month warranty

Related Reads :Best TIG Welder For Aluminum

Best Welders For Home Use – infographic review:

Factors To Consider When Choosing The Best Welders For Home Use (MIG, TIG, Stick)

1. MIG/Flux-Cored Welders or Multifunction

Welders primarily use flux core or require a gas cylinder, or do both. Flux core welding is appealing because it doesn’t require connecting a gas cylinder. However, the flux core leaves a slag layer to be removed.

In general, most of the welders on the market have both MIG and flux cores installed, but some have only one. I would recommend getting a welder with both of these capabilities, as this ensures maximum versatility.

2. Input Voltage

There might be some electrical outlets in the workplace where a MIG welder might not be compatible. Most welders have either 110/115/120V or 220/225/230V outputs, though some have both capabilities.

110 Volt Welders

These welders provide low input voltage so that you can plug them into a standard household power outlet. The only downside is that they limit output power, so you will not be able to weld thicker metal unless you increase your strength or amperage.

220 Volt Welders

Welders capable of producing more powerful welds on thicker metals will require a 220-volt power source, which means an electrical outlet installed. This is essential when working on remote sites without access to a 110V outlet.

Related Reads : Best Trolling Motor Battery

3. Output Power

Different output power specifications are depending on what you’re welding. Some manufacturers include a chart with the welder to help you figure out what setting you need to achieve the highest quality weld.

The chart below illustrates the thickness of metal and the power required to achieve this.

4. Size & Transportability

In determining the type and size of welder you need, you need to consider its portability, weight, and ease of transport.

- If you plan on using it at your home workshop, that weight might not be as important as it should be.

- When working in multiple locations, choosing a welder that doesn’t require a heavy handle to transport is important.

- You can transport a powerful welder in a cart on wheels, but even two people may find it difficult to maneuver it on concrete.

- Depending on the model, the weight can range from 25lbs to 200lbs.

The smallest good quality welders use inverter technology to reduce the weight, while the industrial machines are heavier.

5. Spool Gun

It is possible to MIG weld aluminum with a welder with a spool gun, but you will need to search for one as many of the smaller welders do not possess this ability.

I recommend that you get a spool gun that features a quick-release feature. For example, the Hobart 140 is a great welder that does not include this feature.

6. Duty Cycle

It is also important to consider the duty cycle of the MIG welder you want to use. If you are welding for a long period of time in one go, you will need a motor that has a high duty cycle.

Typically, duty cycles are expressed in percentages; this percentage represents the maximum time that could be operated in 10 minutes before it overheats; for example, a 40% duty cycle could be performed for 4 minutes, and a 6 minute cooldown period be required.

When your welder produces more power, the duty cycle rises, as it takes a while for the thing to cool down.

Small welders without cooling systems experience a higher duty cycle. Many large welders also have powerful fans to reduce the cooldown time.

For buyers concerned about overheating, it’s important to get a welder with thermal overload protection, ensuring the welder doesn’t suffer any damage if the duty cycle is exceeded.

7. Brand & Warranty

When choosing a welder, it is best to select a brand you can trust and rely on.

Manufacturers offer different levels of support, but you will typically find that Hobart, Miller, Everlast, and Lincoln are the best quality and stand the test of time.

- Don’t risk your money by buying a cheap welder with a lousy warranty.

- Hobart and Longevity welders come with a great 5-year warranty.

- These are high-quality anything, but this warranty gives you extra peace of mind.

When researching less well-known brands of welders, make sure they have solid testimonials and reviews.

8. Price

Make your selection based on your budget and what you need. Avoid buying a machine based on the idea that the most expensive one will be the best.

Our guides below will provide you with information on how to choose the best welder for your needs.

If you understand what you need or have a budget, you will accurately select the model to save you the most money and provide you with the best performance.

What You Need To Know About Maintaining A MIG Welder?

Weld quality can be improved by maintaining a high-performance level for as long as possible. While most MIG welders do not require much maintenance, small things can contribute to long-term performance perks.

Cover

Rather than risk damaging your MIG welder with dust, cover it when not in use. Dust can get into welders and gradually destroy them, so it’s better to keep them protected. Most welder manufacturers sell covers specific to their models.

Drive Rolls

When the wire is continuously fed through drive rolls, dust accumulates. Be sure to blow through the rolls every few uses or use a brush to remove the dust.

Contact Tips

Use nozzle dip to coat the contact tips in your MIG gun and prevent spatter from sticking to them. If lots of spatter sticks to the information, this limits the shielding gas flow that prevents contamination.

Other Equipment for your Welder

It’s important to have all the necessary equipment to shield you from harm and ensure that you’ll get the best weld possible with your welder. That’s why we’ve listed some other items to consider when using a welder.

1. Gas Cylinder

Gas cylinders are most commonly used for MIG welding. Different types of welding require different types of gas. Carbon Dioxide gas is the most common welding gas for MIG welding because it has the lowest operating cost.

Other gases, such as CO2, are an alternative to CO2, which is more expensive but provides a higher weld quality and reduced spatter than CO2.

Pure Argon should be used when welding magnesium, titanium, but not when welding ferrous metals such as steel.

2. Regulator

Your gas cylinder needs a regulator before you can use it. There are different types of regulators available, such as gauges, single gauge, and dual gauge.

A gauge on the bottle indicates how much gas is left in the bottle, and another hose is attached to it that will not have a gauge.

3. Torch

You should make sure that your new welder comes with a torch, but you have to check beforehand.

4. Welding Mask

To protect your eyes from the bright arc, which can damage them, you need a welding mask when doing MIG welding. A welding mask lets you see through the weld pool and protects your eyes from the bright arc.

Prices range widely, with the most expensive mask being the auto-darkening helmet, which offers enhanced vision and makes it easier to position the torch while using them.

5. Clothing

While welding, you should wear long-sleeved cotton or leather clothing to prevent burning, and welding gauntlets will protect you. Any flying sparks are extremely hot, and you would not want them to contact your skin.

If your clothing is a synthetic material, you should swap it to cotton or leather since the spark may cause it to stick to your skin and burn you.

MIG Welders: What Are Their Advantages?

A Mig welder is the most versatile and lightweight welding machine in the world because of its versatility. It can join mild steel, stainless steel, and aluminum. It can weld mild steel with gas or with gasless flux-cored wire for fieldwork.

Many of the new Mig welding machines come with the added convenience of multifunction welders, which you can use to MIG weld, TIG weld, and use standard electrodes on the same unit.

The MIG welder easily welds metals together in a small area and can be used at home or on the construction site. With practice, these welders are easy to use and can provide excellent results.

Mig Welders: How do they work?

It refers to metal-inert gas, also known as GMAW, wire feed, or gas-metal arc welding.

- The gas used in MIG welding works as a shield during the welding process and ensures a consistent weld without air contamination.

- If you are starting and need an entry-level MIG welder, these MIG welders make sense. They are easy to use and offer a performance that is professional as well.

- Continual feed accounts for their high efficiency and speed. They are much faster than arc welding.

- Welders that use MIG weld the wire to the workpiece, and, as a result, an arc is created between the workpiece and the electrode.

- Once the welding process is initiated, an electrical current is generated between the workpiece and the electrode.

- In addition, shielding gas is also fed into the weld area to preserve the weld’s integrity.

- This is a great MIG welder for home use. It is one of the easiest to use, which means they are straightforward to use and give professional results.

- Even though many people consider stick welders to be beginner welders, you’ll find that the best MIG welders offer far superior versatility over a standard stick welder.

MIG welding is the preferred type of welding for most welders, as it is the most versatile type.

Types of Welders

Stick Welder

When you stick weld, you must hold the electrode and connect your welding machine to the base metal. As soon as your electrode contacts the base metal, electricity flows between them, creating an arc.

The welds produced by stick welding are not the most attractive. They always require cleaning, and learning stick welding is more complicated because the learning curve is longer.

Stick welding is best for welding outdoors and on dirty surfaces but is not recommended if you’re welding thin metal.

MIG Welder

Electricity flows between the wire electrode and the base metal you’re welding, causing an arc. The arc melts the wire, forming filler metal that joins the base metal, producing an extremely strong weld.

You can use MIG welding for metals of varying thicknesses, as long as your machine is powerful enough.

This method of welding requires very little cleanup, and it produces clean welds. MIGs work well indoors and are an excellent solution for welding in the garage.

TIG Welder

In TIG welding, the electrode is made from tungsten and shielded with a shielding gas nozzle. It is mostly used for welding super-thin metals.

- The filler rods can be of different thicknesses and can be made from a variety of metals.

- This procedure is called fusion because it does not require a filler rod as long as your surfaces meet up at sharp edges.

- Despite its complexity, this type of welding allows the most control.

- Your foot controls the heat, one of your hands controls the filler metal rod, and another of your hands prevents the electrode, which creates the weld.

- Despite its difficulty to master and slower pace than other welding methods, TIG welding produces very good quality welds with excellent strength.

It allows a greater degree of control, making TIG welds more aesthetically pleasing.

Power Supply

Suppose that you just bought a new welder and could not wait to take it home and break it in! However, when you unbox it, you find that it requires a 220v power supply, and you don’t have a place to plug it in.

The problem could be that although this item is designed to be run on a certain amperage breaker, it trips your breakers every time you use it.

Why is this happening? It might be built for a much higher amperage breaker than you usually find in your home.

In most homes, the outlets are powered by 15-amp and 20-amp breakers. But some welders, even if they have 110v outlets, are meant to be run on a 50-amp or 60-amp circuit.

For those homes that aren’t prepared currently, an additional ampacity breaker will have to be added to run the new welder.

You can avoid confusion, headaches, and disappointment later on if you take this into consideration upfront.

Amperage

Welder amperes are measured by the amount of current they produce. Melt-off rate and penetration depth are both controlled by amps. A higher amp will make a deeper weld filled with more material. A lower amp weld will only penetrate shallowly.

Voltage

A voltage is essentially the force of electrical current flowing through a system. It mostly determines what is visible on the weld’s top and does not significantly affect the depth. Low voltage welds will form taller, thinner welds.

To achieve a high-quality weld, the voltage needs to be selected in conjunction with the material. A range of voltages is necessary for achieving smooth edges and broader welds.

Final Verdict

The Hobart Handler 140 is our choice for the Best Home MIG Welder from all the factors we discussed here, because of its well-balanced combination of quality, power, value, low initial investment, and useful features for home welders.

120 volt current is needed, and it can utilize both flux core and MIG welding processes, providing you with a path to upgrade your skills. Hobart is well-known for its extremely long-lasting and durable equipment.

To accommodate multi-process welders, Forney 261 MIG Welder allows you to start with flux core then step up to stick welding, then continue on to MIG and TIG processes.

The AHP AlphaTIG is the perfect companion for AC TIG applications.