- Non-Touch Pilot Arc Plasma Cutter

- Safe And At Low Cost:

- The Compatible Consumables Sets

- Easy operation

- Nominal breaking capacity is ½”

- Precision cut quality.

- High quality of grooving

- Drag cutting technology.

- Built in Air Compressor

- Cuts faster than oxy fuel

- Smaller heat-affected zone for less warping

- No gas pressure settings for flame tuning needed

36 Models Considered

120 Hours of Research

28 Experts Interviewed

400 Reviews Analyzed

With a massive variety of options available for the best plasma cutter in the competitive market, it becomes a different stroke for different folks.

Are you looking for a clean, fast, and flexible metallic cut? If you have a plasma machine, it will not handle the powerful grinding, a disorderly workplace, or rough and inaccurate metal cuts. This tool is an ionized gas torch heated and melted the electrically conductive material to make a clean division or smooth welding.

While talking about the best plasma cutter, The plasma cutters work more efficiently, making clean cuts with less heat and precision, using a plasma torch. Investor technology has reduced the costs of plasma cutters.

The serious plasma cutters remain expensive. It needs a high-quality air plasma cutter that is more suitable for cutting thick metal. It must be efficient energy without too many costs.

Here is our attempted ten criticism of plasma cutters then. We believe that they are the best plasma cutters that are available.

There is also a buyer’s guide to understanding what is needed and what is not available in the different machines. We hope you like it and would like to hear your comments below.

Best Plasma Cutter Reviews & Buying Guide

Let’s find out the best ansi approved plasma cutter ;

Lotos LTP5000D – Best Plasma Cutter For Home Use

The Lotos LTP5000D is a machine made in China that is popular for its low price and high cutting capacity. Lotos can produce such a capable device for such a low cost by using more inferior quality materials than you would find in more expensive machines.

- For example, if you compare the torch handle of a Lotos machine and a Hypertherm, you can see that the Hypertherm torch is made to be more durable and much more abusive.

- The Lotos flashlight still works fine, but it probably won’t withstand long heavy use periods in a harsh environment. The Lotos LTP5000D is designed for people who use their machines in a non-professional setting.

- If you are a weekend warrior and planning to tackle projects like building a roll cage for your Jeep, then the LTP5000D will work very well for that, and you will be pleased with the functionality you get for the price.

- While speaking about the best plasma cutter, This is a plasma cutter intended for hobbyists and beginners.

- So it is neither complicated nor too challenging to learn, which is perfect for anyone who wants to get started with plasma cutting without the complicated setup.

Being a relatively inexpensive machine, we expected it to lack essential plasma cutter functions, such as an air test button.

That would have been a nice added feature when setting up the regulator. However, it does a great job at what most high-end cutters can do due to its price.

Relevant Read : SALARY OF UNDERWATER WELDERS

- Great cutting capacity

- Automatic dual voltage capability

- Cuts efficiently and cleanly through a wide range of metals

- Compact and lightweight design

- Safe and easy to use

- It does not come with a 110V flex cable (purchased separately).

- Not designed for intensive use

Hypertherm Powermax45 – Best Plasma Cutter For The Price

The Powermax45 XP offers excellent versatility for a wide variety of tasks, including cutting, grooving, and marking.

- With a wide range of consumables and a variable power range from 10 amps to 45 amps, this plasma cutter is very impressive.

- This extraordinary machine is very durable and robust. All cables are made from industrial materials, and it is easy to see the sheer power of the Powermax 45, even with the naked eye.

- Brilliant sense technology regulates air pressure to prevent failure, so you don’t need to worry too much about your passing for at least a decade.

- With a cutting power of 45 amps, it is safe to conclude that the Powermax XP is very versatile. You can cut any metal type as long as it is 16mm thick (or less).

- While chatting about the best plasma cutter, It runs on a 50% duty cycle, which is pretty good, although this is not the performance area where the light shines the brightest when the consumables are removed from the photo.

However, because you can easily switch between types of consumables, the XP 45 is quite versatile.

Most people are under the impression that the Hypertherm XP is very expensive. However, its overall value isn’t just price; it’s a superior, powerful plasma cutter with plenty of versatility to make, you can quickly switch between consumables, and it’s very compact and portable. Overall, it is worth the price.

Relevant Read : Â Top 10 Best TIG Welders

- Easy operation

- Nominal breaking capacity is ½” at 20 IPM.

- Precision cut quality.

- High quality of grooving

- Drag cutting technology.

- A little heavy.

Hobart Airforce 12ci – Best Plasma Cutter Reviews

Hobart 500564 is a 12 amp plasma cutter with a nominal thickness of up to 1/8 “and cuts up to 1/4” through mild steel and stainless steel.

- The integral air compressor unit, together with the inverter design, makes it a lightweight company used at home and in small workshops where metal cutting is not intensive.

- Hobart 12ci is comparable to the AirForce 27i immediate release plasma cutter, which is more compact but more powerful and more expensive with increased thickness of cut, double tension, and improvements in other areas. However, it does not have an air compressor like the 12ci model.

- Although it has a low breaking capacity and does not offer an option to adjust the output amperage, it leaves a clean finish. It works from a standard outlet and will do the job within the tolerance of the meter.

- It’s a shame that most standard Hobart flashlights measure 12 ‘, but it’s a minor detail compared to the flashlight quality.

While speaking about the best plasma cutter, If your cutting range is minimal and product virtue is essential to you, the Hobart Airforce 12ci is a machine worth buying. Otherwise, you can get more for a lower price, but with less quality in the Mophorn 40 Amp Plasma Cutter.

Relevant Read : Best TIG Welder For Aluminum

- Price range: low

- Five years warranty

- Dimensions: 15 “x 18.5” x 11.2 “

- Weight: 26.7 pounds

- High-quality components

- Lower amperage and duty cycle

Miller 625 – Top Plasma Cutters

The Miller Spectrum 625 X-Treme is a model specially made for people who like lightweight constructions or for DIY enthusiasts.

- The product is available in a lightweight design, making it a highly flexible and portable plasma cutter that can be easily transported from one job site to another.

- Plus, it is heavily built and can withstand the impact of long working days.

- This cutting plotter offers exceptional versatility as it can be used in a variety of work environments.

- If you are one of the people who judge performance based on size, then you are wrong with this product.

- It is lightweight, and that does not affect performance and functionality.

- It is packed with features that set it apart from other products in the market. Read on to learn more about the features of this product.

- The Miller Spectrum 625 X-treme is a small plasma cutter in size and weight but can generate enough power to cut various steels.

With this plasma cutter, you can clip several conductive metals, such as stainless steel and aluminum, as well as mild steel.

The Miller 625 plasma cutter is packed with features that increase performance and reliability. Although it is available in a compact design, it can generate enough current to cut various conductive metals.

Relevant Read : BEST WELDING HELMETS FOR MIG

- Very portable and powerful

- Very convenient to use thanks to some valuable features it has.

- It is versatile and has wide applications.

- You don’t have to break a bank before you can buy it.

- Limited to light to medium cutting tasks

Eastwood Versa Cut 40 Amp – Best Home Plasma Cutter

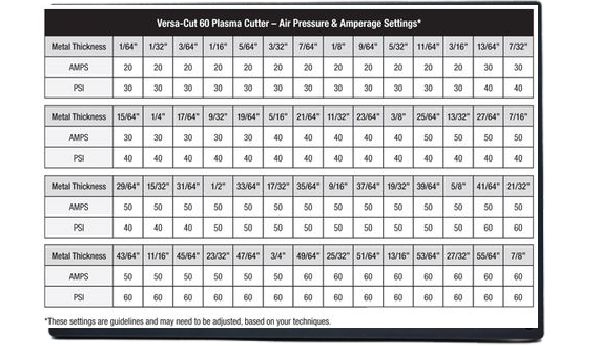

The Eastwood Versa Cut 40 Amp plasma cutter offers high quality at significant savings. This machine offers 40 amps of cutting power, has dual input power, and operates on 110/120 or 220/240 volts using an N50 cord adapter.

- Connect the 120 wire to the N50, and the machine will automatically detect that it is connected to 240 volts.

- With a 60 percent duty cycle at full power, the Eastwood Versa Cut 40 Amp plasma cutter can make clean cuts in sheet metal as thin as 24 gauge.

- You can set the air pressure and power output individually, providing a lot of versatility once you get used to using this plasma cutter.

- This machine has a high-frequency arc start, so it is not suitable for the CNC plasma cutting table.

- The Eastwood Versa Cut 40 Amp plasma cutter features a Trafimet CB50 torch with over 20 feet of cord and is an industry-standard piece.

The Eastwood Versa Cut 60, the second-highest in the Eastwood line, gives you the ability to cut up to 7/8 inch steel at a great price, but it’s only a 220V machine.

Relevant Read : BEST BUDGET WELDING HELMETS UNDER $100

- Use of transducer system for arc stability and improved cutting power

- Built-in pilot arc for instant arc and incredible ease of use

- Internal moisture separator to transport clean, dry air to the torch

- Voltage sensing technology to help select the correct voltage

- Almost impossible to cut aluminum with 110v

Hobart Air Force 40i – Plasma Cutter Review

The Hobart Airforce 40i is the most powerful and expensive model in Hobart’s plasma cutter line. Its outstanding performance, fast cutting speed, solid duty cycle at high amps, and incredible reliability make it an ideal choice for everyone.

- You need a plasma cutter for non-industrial or even light industrial use.

- Hobart is an established name among welders, known for its robust, high-quality systems and reasonable prices while talking about the best plasma cutter.

- They are now in the plasma cutter market, and their legacy remains just as strong.

- With a range of technology and safety options in a reliable, hard-working frame, this is an excellent system for anyone looking for a heavy-duty, heavy-duty plasma cutter, whether for use at home.

- While the Hobart Airforce 40i may be more expensive than many cheap plasma cutters, it’s worth it, for God’s sake.

Once you’ve used this plasma cutter, with its plethora of automatic functions, clean results that take almost no work to prepare, and most importantly, blazing-fast cutting speed, you’ll never want to use anything else.

Relevant Read : Best welding helmet in

- Powerful cutting performance

- Has an improved wind technology system

- Suitable for cutting metal surfaces and do, coated or painted

- Provides a precise cut and produces less slag.

- Easy to set up

- The grounding clamp is relatively weak but easy to attach

- Shorter power cord, so you may have to wiggle it a bit

Canaweld Cut 45D – Best Value Plasma Cutter

Canaweld is not known as American market leaders such as Lincoln, Miller, Forney, and Hobart.

- Still, its products are used throughout Canadian manufacturing, and the American market is growing for its Canadian-made plasma cutters.

- The Canaweld Cut 45D is very portable and has a shoulder strap. With 45 tap amps, it is capable of cutting a 5/8 inch mild steel plate.

- It comes with a high-quality European TRAFIMET flashlight, a favorite in the US and beyond. Canaweld backs the Cut 45D with a 3-year warranty.

- Canaweld designed the Cut 45D for tactile arc starting, avoiding digital equipment interference associated with non-contact HF starting.

- It also has an automatic arc reset to skip gaps for mesh or grid cutting.

This is a powerful machine with excellent performance, with a 100 percent duty cycle at 30 amps, allowing the Cut 45D to cut ⅜-inch steel plate continuously.

Relevant Read: Best auto-darkening welding helmet

- Automatic arc reset for mesh and grid

- Built-in dirt and moisture filter

- The pilot arc starts for paint and rust.

- Automatic pressure adjustment

- Includes TRAFIMIT European cutting torch

- 240 input voltage

LOTOS LT5000D 50A Air Inverter Plasma Cutter Dual Voltage – Top Rated Plasma Cutter

The LOTOS LT5000D 50A Air Inverter Plasma Cutter is extremely popular for its enormous versatility. Switching from one torch style to another is also a simple process.

- Controlling air pressure for perfect airflow is always a challenge when things are done manually.

- An automatic control system can also be a great advantage for beginners and experienced workers.

- Thanks to the Smart Sense system that ensures that the air pressure is correctly adjusted.

- It should be noted that the more you focus on LOTOS LT5000D 50A Air Inverter Plasma Cutter, the further you are from buying an inexpensive plasma cutter.

- This pays close attention to the overall performance of the model.

- Fabrication shops, auto repair shops, industrial pipefitters, and plumbing companies are some of the places where this plasma cutter will be most productive.

It is also ideal for industrial repairs, expanding farms or farms, and a metal robot in factories.

Relevant Read : MIG vs. TIG Welding

- Increased arc energy promotes more delicate cuts

- Consumes significantly less energy when cutting expanded, painted, or oxidized metal

- The cutter is second to none

- Safer and more comfortable

- A little expensive

Everlast Power Plasma 62i – Best Home Plasma Cutter

The Power Plasma 62i features a Blow Back auxiliary arc start for easier starting with rust and paint and has super bright control displays for easy reading in bright light while wearing safety gear.

- The 60 percent duty cycle at 60 amps is impressive for a plasma cutter in this price range.

- Everlast is designed with automatic pressure adjustment that changes pressure by several inches per minute for a clean cut.

- There is a 3-second tip timer that turns the torch off if no amount is made after three seconds of arc time.

- Grooving ability is an unusual feature for machines in this price range, and this cutter features digital arc control to maintain an optimal cutting temperature to produce clean cuts.

- To work with a generator, it must have at least 11,000 watts of “clean power” (fixed with no signal fluctuation), or the warranty will be void.

Adjustable post flow timer sets the time for airflow after cutting. Everlast offers a 5-year parts and labor warranty on its plasma cutters.

Relevant Read : Types of Welding

- Blowback pilot arc for easy starting in case of rust

- Includes a grooving function

- 60 percent duty cycle at 60 amps

- CNC terminated with the computer connection socket

- Adjustable post flow timer

- Requires “clean energy” generator

Lincoln Electric Tomahawk K2807-1 – Best Plasma Cutter

Lincoln Tomahawk K2807 is a well-equipped plasma system for industrial applications. With a cutting thickness of up to 5/8 inch and acute up to 3/4 inch, the unit is rated for up to 35% duty cycle at 40 amps.

- The device’s mechanical and electrical strength can encourage anyone to use it in almost any plasma cutting project.

- But for optimal performance and longer life of torch and consumables, recommended applications are listed below.

- Those looking beyond the following works should look for more robust and heavier models.

- You can rely on the machine for standard and contact/drag cutting and grooving.

- The cutting thickness has already been mentioned, but the consistency you can cut depends on the metal you choose. The same goes for speed.

Aluminum can be cut 10-20% faster than mild steel and 30-40% faster than stainless steel. Again cutting mild steel should be 10-20% faster than stainless steel.

Affordability is a bit of a far-fetched idea in this regard, but concerns about quality and smooth cuts in mild and stainless steel are not.

But you can’t expect great results with an aluminum workpiece. So buying Tomahawk 625 can be a combination of winning and committing if you want to accept that.

- The variable arc with continuous output control

- Tap to start the arc

- Automatic ignition technology for grid cutting

- 20 ft torch cable

- Comes with an air regulator and pressure gauge.

- 240 input voltage

How did we tested the Plasma Cutters?

At WeldingZIlla, we are dedicated to finding the best plasma cutter for our reader. We understand the importance of choosing the right plasma cutter for the quality and efficiency of cutting tasks, which is why we take the testing process very seriously.

To find the best plasma cutter, our team conducted a series of tests in our labs. First, we gathered a group of experienced welders and metalworkers to test out different plasma cutter models. This allowed us to get a wide range of feedback and insights from people with different preferences and needs.

Next, we set up a series of test stations to evaluate the plasma cutter’s performance in different areas. We tested for factors such as cut quality, speed, and ease of use. We also tested the plasma cutter’s durability and reliability under different cutting conditions.

After gathering all of the data, we analyzed the results and compared the different plasma cutter models. We paid special attention to the feedback from the testers, as their experiences and opinions were crucial in determining the best plasma cutter.

Finally, after thorough testing and analysis, we were able to identify the top-performing plasma cutter. We are confident that this plasma cutter will provide our customers with the highest level of performance and reliability while cutting metal.

Overall, our team is committed to finding the best plasma cutter for our customers, and we hope that our efforts will help make their metalworking tasks easier and more efficient.

Best Plasma Cutter – Buying Guide

POWER

The type and thickness of metal are factors that we need from the best plasma cutter’s power. The ability of a unit is essential to determine its cutting capacity and to reduce quality. The output power also affects the working cycle of the model.

Implementation of the mill units can generally be found in the workshops for the house performed at the standard points of sale 120V, 15A. However, high-quality or industrial flares require 20A or even 50A and 220V to implement efficiently.

The first step to determine your energy needs is to consider the metals’ thickness with which it usually works. Although plasma machines can cut all gradual stainless steel things, there are some things to believe in the purchase.

A 25A plasma flashlight will work perfectly for something to ¼ “. For metal to ½” thick, do not go under 40a, and when it comes to cutting plates of 1 “, buy a machine with a 60A current or more.

The next step is to determine what kind of energy you have available in your workshop or home. To reduce metals that have ½ “or thicker, you may need a 220V output. Contact your electrician to ensure that your energy infrastructure is sufficient to support a plasma cutter.

The power output determines the input power of the device. Although you must buy a cutter with sufficient energy for your needs; Excessive expenses in too much force can be reckless.

Relevant Read : Â Best Welding Helmets for Beginners

Severance thickness

The thickness of the separation is the maximum thickness that the plasma cutter can cut through metal. However, it requires that an edge can effectively shorten the metal. In the thickness of the compensation, the cut will be prolonged, and the machine does not produce enough heat for a clean-cut and becomes robust and full of scum. The cutting metal in the separation’s thickness is not recommended for the regular amount or reaching the best results.

Air supply

Most hand plasma cutters use normal air for the cutting process. Sometimes it can be difficult and consuming a lot of time to transport bottled gases together with the plasma cutter, so to reduce thinner materials and simple portability, you can get a plasma cutter with the built-in air compressor, because this will not only be saved money, but it makes it Also the plasma cutter light and portable.

Environment

The environment is an essential factor that should be taken into account when buying a plasma cutter since a dirty environment is clear to provide a contaminated air supply to the plasma cutter, affecting the cut’s accuracy but possibly influencing the durability of the device.

There are plasma cutters with built-in fan or wind tunnel technology specially designed to provide better accuracy and reliability for heavy powder forms or metal chips.

In the design of the wind tunnel, the cooling air is filled by the device in such a way that the air is not blowing on the electrical component and dirt and powders cannot be installed on the PC plate or that is vulnerable to the design of the fan on request The cooling fan performed if necessary, avoiding dirt or dust component to enter the device.

These users who work in dirty and dusty environments can go through the plasma cutter with these technologies.

Pilot arch

The best plasma cutters have a pilot arc as a cutting function that means they can cut without the torch of the torch that makes contact with the metal. The pilot arch helps to cut the painted and rusty surfaces.

Don’t forget that you must clean the area where you connect the ground clamp if you cut rusty or painted bodies. If you go through the metal with gaps between the metal, such as the mesh blade, you do not have to stop and start the torch because it stays illuminated with a continuous bow. Most soldiers, except Chinese, will have a pilot arch.

Relevant Read : Â TIG WELDING STAINLESS STEEL

Control panel

The device control panel is a significant factor because most of the plasma cutter with which the user can perform the device. One must always search for the plasma cutter with easy-to-read and easy-to-understand and all possible indicators.

For inexperienced users, it is imperative to understand the controls to use the device. If the species controls are simple, even a beginner can use the plasma cutter with a stream. You can search for the plasma cutter with a built-in consumable compartment mounted on the device control panel for more beliefs.

Price

The price is a significant consideration when buying a plasma cutter. It is easy to go to a cheap Chinese plasma cutter, but make sure you know the risks.

A mean machine’s useful life will be much shorter than a soldering iron executed in the US. UU or is a reliable man factor. Hypertherm, Hobart, and Miller are reliable and of excellent quality and can easily take 3 or 4 times longer than a cheap plasma cutter, which is one of the reasons why they are more expensive.

Relevant Read : Best Stick Welders (Arc Welders) “ Top Picks and Reviews

Built-in inverter

Users who regularly work on external sites where there is no power outlet or that with mobile services can face some difficulties in using the standard plasma cutter, so some plasma cutters are available with built-in investors for these purposes.

These plasma cutters can take the power of CC and can feed through a high-frequency transistor inverter from around 10 kHz to approximately 200 kHz.

The plasma cutter with a built-in inverter can be pretty expensive but offers extra portability. It is the best option for those users with mobile services, such as due to high-frequency switching production, the plasma cutter housing is made much smaller.

Voltage

The plasma cutters that run out without current input 110/115 / 120V are compatible with their standard internal power supply. These are excellent for beginners or if you use them at home but are limited in the power they produce.

If you want a little more energy, you will need one with a 220V input, which is only compatible with generators. If you get a plasma cutter with a power of 110 V and 220V, you have the option to use power supplies, so these are my favorite typing because of your versatility.

Amperage

The current of a plasma cutter gives the thickness of the metal capable of cutting. E.g., Animal power in amperage 30a must be comfortably cut the 3/8 inch metal. But an output power 12a can only cut about 1/8 inch. If you use a capacity of 220V, you can get a higher current strength and cut a thicker metal.

Weight

The weight is always something to consider buying equipment because it doesn’t want to take too much heavy equipment. Fortunately, most plasma cutters are relatively light these days, thanks to the technology of the investor.

If you buy a plasma cutter with a built-in air compressor, it may be a bit heavier, but this remains much more portable because you only need the plasma cutter, and you are ready to go.

Safety

Finally, but not least, you must take safety into account as your number one priority. Read everything via all security instructions in the instruction brochure by your selected plasma cutter.

Although the arc is not so intense as a welding arc, it can damage your eyes, so try a few shadow glasses 3 or 5.

You must also wear gloves, Mig or TIG gloves that are not too bulky, let yourself feel What you do, what you protect. Do not use synthetic material gloves because they can melt and stick to your skin.

Always go with leather. Cover your body, legs, and arms with durable cotton material to protect it from sparks and bow. Finally, when cutting the metal, use a few boots with steel protection to prevent injuries.

Portability

However, the portability factor is not essential for every user, but for some users, it is much crucial. The size and weight of the plasma cutter are significant for those who need a portable plasma cutter.

If the device is not required to be moved and the materials to be cut to be removed from the plasma cutter, it does not matter even if the machine can hardly move.

If it is required that the plasma cutter is often pushed to the materials needed to cut, the device must be portable and easy to transport without any difficulties. Nowadays, you can quickly get a plasma cutter designed in a way more compact for more portability.

Relevant Read : BEST EVERLAST TIG WELDER “ Reviews & Buyer Guide

Duty cycle

The working cycle is one of the essential aspects that you must take into account the plasma cutter. In simple terms, indicate the plasma cutter’s ability to perform under a specific load for a particular duration.

To buy a high-quality plasma cutter, you have to look at the average thickness you could cut. For example, a plasma cutter can make a 0.25-inch cut. Pushing outside this limit can focus on the accuracy and cleanliness of the separation.

In general, a lower working cycle suggests optimum performance for a limited period. As soon as this expense is complete, the account can be degraded, and it takes longer to complete your project.

On the other hand, for heavy working projects, a working cycle of 50-60% will be sufficient. In the previous discussion, most plasma cutters with an operational process are from 60% to 50 amps.

Consumables

A standard plasma system uses five different consumables. They are the shield, the swirling ring, the holding lid, the electrode, and the nozzle. The protection protects the rest of the molten metal consumables and sparks.

If you don’t have a lot of experience with such machines, go to a trailing shield. The holding lid jointly reserves the stack of consumables.

The size of the nozzle plays a crucial role in the ARC enforcement. The electrode can drive the stream of the torch to the plate. Besides, they complete the electric circuit. The swirl ring leads the gas in different plasma cutter directions and removes it to the torch. It is known that consumables avoid incineration of the mouthpiece.

Accessories

Your selected plasma cutter must be supplied with the correct accessories that allow you to work efficiently and safely. While working on a plasma cutting project, you need a suitable helmet to protect your eyes.

The gloves protect your hands. In the absence of these accessories, it can hurt while working.

When working on plasma cutting projects, it is essential to use a leather jacket. Protect your clothing and skin against sparks. If you don’t wear thick leather, all your clothes have holes that have been developed in them.

The central hat is a useful accessory that protects you from burning the upper part of your head. A car is a valuable accessory when you often want to move your plasma cutter.

The versatility of the cut

Before you continue with the purchase, you will receive sufficient information about what a plasma cutter can be cut. Most plasma cutters can cut electrically conductive material. The reason is that there must be a complete electrical current that returns to the unit through the ground clamp and the workpiece.

A decent quality plasma cutter can be perfect for stainless steel, alloy steel, mild steel, aluminum, copper, etc. The versatility of the cut helps to use the same plasma cutter for different projects. Besides, you must also check the thickness of the material that can be traversed.

Uses Of The Best Plasma Cutter

Before buying, it is essential to know what kind of plasma cut is going to do.

Industry

Plasma machines play an integral role in optimal and cost-effective production. The mass production lines or pieces should be as effective concerning time, effort, and costs.

- This is not always possible with conventional cutting methods.

- Plasma flares that are mounted and capable of programming to reduce specific patterns or lines play an integral role in lowering import costs per unit.

- Not only are they more accurate, but they also work faster than grinders or saws. The cutting surfaces also require less preparation for assembly or installation, such as the plasma cutting results in less slag.

- When it comes to cutting industrial, there is very little space for errors.

- Programmable flares eliminate the risk of minor mistakes that can lead to significant losses for industrial companies when they differ in thousands of units.

- Plasma machines are generally used in industrial processes where aesthetics and precision are essential. High-tech production processes often require this method of cutting and steel welding.

This industrial technology is one of the most profitable ways to ensure that companies have complete overproduction control.

Although these units’ installation can have high initial costs for the production sector, it often performs long-term savings if consumables are usually lower. Consumable prices are also lower, especially if companies buy bulk.

Art cutting

Before the torch cutters were made immediately, metallic artists were seriously limited in terms of precise cuts.

- The methods that they had at their disposal were unmanageable and ineffective. Artists also do not always have complete control over the results of their art projects.

- Because metal torches were readily available, artists have the means for massive products and have more ways to refine their art.

- They can apply many different topics to their work, which may not have been possible with conventional tools.

- Art is a subjective-objective, and without suitable tools, artists can experience frustration in their attempts to express themselves or achieve the levels of creativity they want.

- Using ionized gas and appropriate accessories, artists can now make minor cuts and create complicated designs and complex.

- The flashes of ionized gas go a long way to eliminate creative limits for metallic artists.

As a metallic artist, you may not need a duration or a robust model. However, it is essential to remember that you have to buy a high-quality system. This ensures that it receives many years of service from its cutter and perfect metal cuts, and precise welding.

Automotive use

If you have a garage or an automotive or amateur professional, you need a plasma system to cut the car. The metallic cut is inevitable while restoring, repair or adjustment of the vehicle.

The slicing applications are generally related to removing parts or components of the body, manufacturing new parts, cutting nuts and screws, and preparing welding surfaces.

- If you are in an automotive company, portability is your best friend. Be sure to buy a unit with low weight and simple portable functions, such as a handle.

- When working with automotive metal, you can often find rusty or painted surfaces. The units with a pilot arc say you do not encounter problems when cutting pieces like this.

- The torch should also be small and mobile so that it can come in small corners and holes.

- During the manufacture of the automotive metal, it usually does not have to cut more than ½ “.

- Although you can settle with the energy output at the middle points, you try to adhere to high-quality models.

When you are opposed to metals, it is more likely that you have done work well, even if it takes you a little more.

Domestic use (manufacture)

As an owner, you often have to cut by metal to make repairs or maintenance. There are many applications for a torch around your home. Home requests for these units include plumbing, housing glass repairs, general repairs such as garage doors, and the manufacture of specific accessories.

For domestic manufacturing, portability may not be as important as sustainability.

Because you do not use your cutter for commercial purposes, it is essential to choose a unit that uses conservative conservatives and has a less life duration. The asset requirements depend on the metal thickness you want to cut, so make sure you have this in mind.

FAQS (FREQUENTLY ASKED QUESTIONS)

Why use a plasma cutter?

The plasma cutters are the best way to cut the metal. They cut much faster than ox fuel and are more accurate due to a smaller cutting width.

This means that the surrounding area is not affected by heat and can be more specific with the cutting room.

The plasma cut can also cost any conductive metal, including stainless steel or aluminum, so it is a versatile option.

What kind of cut are you doing?

The work you want is your most important decisive factor. If you only cut a metal sheet, you do not need a large 200 AMP plasma cutter expected for a steel plate of 3/4-inch.

For automatic authorities and other light service tasks, a smaller machine costs less to buy and walk with a 120-volt power for additional savings.

Which power levels are necessary?

When considering energy needs, it is first the assets and the work cycle. This decides the upper limit that can reduce and will also determine whether you need a 240-volt input or if you can get 120 volts. You can determine that it is more versatile to have double voltage feed energy from 120/240.

Do you need a source of air pressure?

Some machines are equipped with a built-in air compressor. Others need external air from a separate air compressor. Depending on the size of the plasma cutter, a compressor can add a high cost on board. Although it is necessary to buy a separate air compressor, it can probably be duplicated as a diet for spray guns and air tools.

How do you set up a plasma cutter?

The configuration and use of a plasma machine are relatively simple.

- Before configuring, it is essential to know that the plasma cutting work works through a complete electrical current, which means that it needs, similar to welding, a nature clip.

- The first step is to ensure that it has a safe work surface. There must be enough space for your workpiece, and you must be able to move freely around the table.

- Then, after you have ensured that the device is out, enchant.

- If your unit requires an external air compressor, the next step is to configure your cutter to connect the compressor.

- Connect the connection by returning the outer ring and inserting the male connector. Insert the airflow so that there is constant air pressure.

- Then place your workpiece on your work surface and connect your ground clamp to the workpiece. To get the best results, make sure that you keep the ground wire in the area where you cut.

Then switch on the device by moving or pressing or pressing a switch behind an “On / Off” or “Power” unit. This will activate the plasma arc. To start cutting, take your mouthpiece near the metal surface and pull the trigger.

What can the plasma cut?

Most torches can cut electrically conductive material. This is because total electrical power must be back to the device through the ground clamp and the workpiece.

Electrically conductive materials can accommodate the flow of an electric current in one or more directions and are typically made of metal. An electric current is the current of negatively charged electrons or positive or negative ions.

Operators generally use ionized particles for cutting metals such as copper, aluminum, brass, steel, and stainless steel. This list is not exhaustive; You can also cut other electrically conductive materials.

Can a plasma cutter cut wood or plastic?

One of the most considerable inconveniences of technology otherwise integral and practical of these systems is that it cannot reduce non-conductive materials. There is no power for the plasma stream when there is no electric current back to the workpiece unit.

Besides, the heat produced by these units can be harmful to non-conductive materials. However, there are affordable tools that specialize in cutting materials such as wood or plastic. To cut different types of metal, nothing exceeds the speed and accuracy of a plasma cutter.

Is it worth the cheap plasma cutters?

As a general rule, the long-term value has been obtained from these machines more than high-end products. When you buy a cheaper cutter, you cannot expect that you can receive optimum quality, durability, and energy.

It depends on your unique needs. If you need a two-inch cutting machine from a ¼ “-sheet, the purchase of the cheapest equipment is recommended. On the other hand, if you need anything, you can live in a cheap plasma cutter every day. It’s not worth it.

The potential value obtained from a high-quality unit and high performance often triumph about the initial costs it saves. This is because the cheapest models usually take longer to make cuts. They also use consumables at a faster speed, which can increase their operating costs over time.

Benefits Of Using Best Plasma Cutter

The plasma cutters can be valuable additions to a workshop. First, it is one of the fastest ways to reduce material that carries out electricity. This is because preheating is not necessary.

- When you enable the torch, you can cut it immediately. The torches are also versatile and accurate. You can perform perforations, welding repairs, or cuts at corners or complicated forms without any problem. The cutting columns also offer the latest accuracy.

- The thing that has much more important is the quality of your cut. Say goodbye to the destroyed and serrated edges. There is a close integration between the cutty type and the unit’s software, which means that accurate cuts can make.

- Finally, the use of the products is straightforward. They can use even inexperienced or starting metal manufacturers efficiently. The highest definitive systems are also safe because they may have exhaust units to channel user smoke.

CONCLUSION

Regardless of its capacity as a metal worker, one thing is clear: a sustainable plasma machine is worth in gold.

The above items are tested and examined by real people who often use their devices. Choosing a product from our list makes it a satisfied customer every time you choose one that meets your needs.

Consider the following aspects when buying a plasma torch: cutting width, asset exit, work cycle, use of consumables, and costs and portability.

When you find units with requirements that match your needs, you can decide the quality and price.