19 Models

Tested

110 Hours of Research

18 Experts Interviewed

18 Articles

Analyzed

What Size Generator For Welding?

Generator Sizing Chart for Welders

| Welder Amperage | Minimum Generator Size | Recommended Generator Size |

|---|---|---|

| Up to 100A | 3000 watts | 4500 watts |

| 120–160A | 4500 watts | 6500 watts |

| 180–200A | 6500 watts | 8000 watts |

| 210–250A | 10000 watts | 13000 watts |

Welding jobs sometimes require work to be carried out on the job site rather than in your shop. Traditionally, welding has been carried out by large generators. However, with generators today, and you can weld at remote locations.

How to Size a Generator for Welding

The generator output is usually expressed in watts. Wattage is equal to amperage times voltage, so a 2200-watt generator can charge a battery 400 times. A generator rated at 4800 watts might charge a battery 400 times.

By multiplying by 800, kVa output can be converted to watts. For instance, a generator rated at nine kVa can be converted to 7200 watts.

You should use a generator with two ratings: a steady ongoing load and the second for a short burst.

This quiet inverter generator produces less than 3% THD, making it attractive for powering any 120V or small 240V welder.

Generally, the startup or surge watt rating is 25-30% higher than the running watt rating. This is normally reserved for motors starting.

Some brand names indicate the wattage of the generator. Check whether it refers to running watts or surge watts, as these values will differ from manufacturer to manufacturer.

A generator must be sized for the maximum wattage the welder will draw

to operate at full capacity. Once you determine the wattage, you’ll know only the minimum wattage needed to run the welder.

How Many Watts Does Your Welder Use?

While talking about the generator for welders, Some manufacturers provide minimum generator size recommendations for welders, but it’s rare to find total wattage listed for welders.

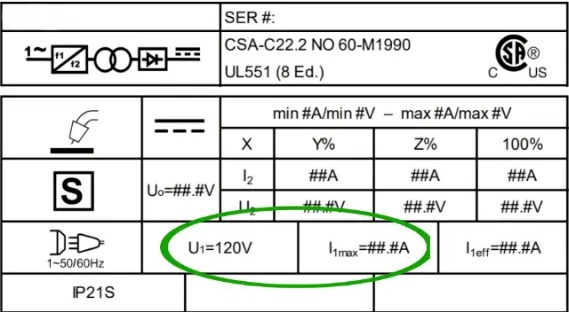

Even though some manufacturers won’t provide wattage information, you can usually figure it out by using the voltage and amp figures from the manufacturer’s instructions or the data plate on the welder.

Use the Manufacturer’s Voltage Rating

Welders used by some manufacturers are rated at 230, 115, and 110 volts but may be powered by 120 and/or 240 volts.

The manufacturer’s number U1 is best used to verify the machine’s accuracy as that’s the voltage the company uses to rate it and to determine how much amperage it uses.

Get the Right Amperage Value

Welders can come in a variety of amp ratings, or it can be just one.

Look for the I1max rating on the electrical device because it represents the largest rated supply current. The I1max number may indicate the maximum “surge” current draw on startup.

Upon multiplying your Imax current with the manufacturer’s voltage rating, the maximum wattage required to operate your welding machine will be obtained.

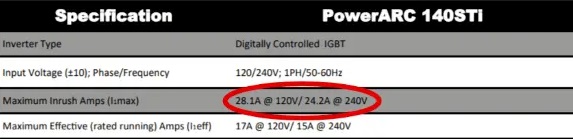

While talking about the generator size for welder, The manufacturer’s required minimum recommended surge generator is 6000-watts for the 140 STi. In the owner’s manual of this welder, the manufacturer recommends that the electrical system be run at 24.2 amps multiplied by 240 volts.

We expected the 120V, small 240V transformer welders to work well with the inexpensive Westinghouse generator. 240V transformer welders up to 250 amps will be handled easily by the more powerful model.

It is normally used to size dedicated building circuits when we consider rated duty cycle limits (idle time) and heat buildup. Without making adjustments, it is too low to calculate the maximum watts.

As I found out from several companies, the I1max rating is normally more than twice as high as the I1eff rating when manufacturers give both ratings.

As an example, a Lincoln 140 data plate only shows an I1 or “recommended circuit breaker” information.

The I1max rating of this machine is likely closer to 25 amps, given that 20 amps times 120 volts is around 2400 watts. That’s why Lincoln recommended a 3000-watt generator for this welder.

While talking about the generator for welder, It may be too small a size to determine the maximum wattage of the circuit breaker to calculate full operation. A properly operated circuit breaker will be time-delayed and would probably not trip because a brief 25 amp surge occurs.

Surge-rated generators have surge ratings of above 2400 watts, which would cause a problem.

In conclusion, do not rely on continuous output amperage figures such as I2 or duty cycle amperage.

Relate Article: Best TIG Welding Gloves -Top Picks , Reviews & Guide

Adjustments to Consider

A few other things need to be considered before choosing what size generator will run your welder.

Derate for High Altitude Operation

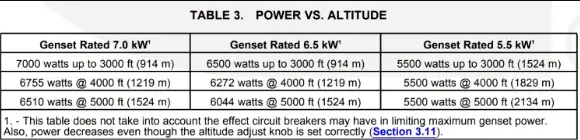

As air thins, power drops at greater altitudes.

A generator manufacturer told us:

With the increase in altitude, air density decreases, so that rated Genset engine power drops so as to approximatively 3.5 percent for every 1000 feet (305 meters) reached (Table 3). Therefore, fewer appliances do get turned on.

Don’t Forget Accessory Equipment

Consider the additional wattage requirements of any fans, lights, and compressors that you need during welding.

In a team situation, you’ll need power generators that can supply twice your welder’s maximum watts, so you’re not out of luck after you start grinding and cutting with machines that draw over 1800 watts apiece.

“Dirty” vs. Clean Power Generators for Welders

The internal powers of welders can be divided into two distinct design categories, each supplying current in various ways for weldable power output.

Traditional Transformer-Based Welders

This heavy power source provides welding power with transformers made of copper and aluminum that alter AC current into low voltage/high amperage DC power.

Welders with the traditional method work well with any generator. They are reliable and do not respond to dirty power.

Relate Article: Best TIG Welder For the Money- Reviews & Buyer’s Guide

Generators for Welders

With its slim design and reliable construction, a modern portable generator is great for powering your welder and other tools at any job site and keeping your lights on at home when the power is out.

Conventional Generators for Welders

The simplest type of generator is an alternator that spins at 3600 RPM to produce 120 volts with a 60 Hz frequency.

Variations in this speed cause voltages and frequencies to fluctuate, which can result in harmonic distortions. Even though the governor attempts to keep an active RPM, any significant variation in load will cause a brief spike in the rotation rate.

Traditional transformer-based welding works well with conventional generators, but the power they generate does not meet the standards. This type of generator should not be used with inverter-powered welders needing less than 5% THD.

Inverter Generators for Welders

Welding inverters produce consistent results for generators as well because they operate in three steps:

- An engine-driven alternator can produce high-frequency AC.

- Taking AC current and converting it to DC

- An inverter can be used to convert a DC current into a very stable and lower AC current.

Relate Article : BEST WELDING HELMET -TOP PICKS AND REVIEWS

Tips for Welding with a Generator

Size the generator to your welder:

You must know the wattage required by the welder in order for it to be fully operational. An approximate calculation is: Multiply I1max (max amps) by U1 (volts) = maximum watts.

Consider how much energy to put into optional welding accessories such as lights, fans, etc.

Power loss is approximately 3.5% per 1000 feet of altitude.

To maximize your chances of success, choose a generator that produces at least 25-30% more watts than you need.

While talking about the generator for welder, Welding becomes more difficult when using an undersized generator, as it can have higher voltage spikes and frequencies.

Load fluctuation will be handled better by a generator running at 50% to 60% of its capacity than by one running at 90% +.

- Starting and Shutdown: Make sure the welder is unplugged before starting or stopping the generator.

- Auto-Idle: The generator must always run at full speed when connected to the welder, so you disable any fuel-saving feature.

- Fuel: Make sure your generator has fresh fuel. Don’t let the generator shut down while connected to the welding machine especially when you may be running a bead.

- Maintenance: The generator should run well. Do not operate the welder with a generator that has malfunctioned.

- Power/Extension Cords: Welding extension cords should not be used if they are undersized or in poor condition. Here is how to measure a welder extension cord.

FAQs : About Generators for Welders

Will A 3000 Watt Generator Run A Welder?

That depends on the welder’s voltage and amperage ratings. A 3000 watt generator can run a welder rated at 120 volts and less than 120 amps. However, it will be running at full blast the whole time. A larger generator would be more suitable for a welder with higher output or voltage. You can use this formula to calculate the watts needed for your welder:

Watts = Volts x Amps.

How far will a 3000-watt generator run a welder?

A 3000-watt generator at 120V can produce 25Amps (Amps = Watts /Volts). Most 120V welders draw more amps than that at full power, but high output small welders can produce up to 100Amps.

How much power does a 5000-watt generator need to run a welder?

This includes many 120V welders with an output rated up to 160 amps, which takes less than 40 amps at startup.

Several 240-volt machines draw more than 20 amps during startup, and they need over 5000 watts to operate at their maximum capacity.

Is a 140 amp welder capable of being run by a 400-watt generator?

In many cases, welding machines rated for 140-amp output will draw less than 30 amps at startup, but they can draw as much as 40 amps.

Make sure you have the I1max (max amps) rating and multiply that by the voltage for the maximum wattages. A 140-amp welder will require between 3600 and 4800 watts to work properly.

Conclusion

The research regarding what size generator to buy for an existing welder is still ongoing, and some of you have a generator but wish to know what kind of welders it can handle.

Either way, you are now armed with the information you need to make an informed decision in terms of the unit’s recommended wattage.

The ideal combination of a welding machine and a generator will give you up to 30% more capacity than you need. However, a combination of only 80% capacity may also make sense for you.

You will make a call based on your situation. We have to balance power, price, and portability when sizing an economic generator for welding.