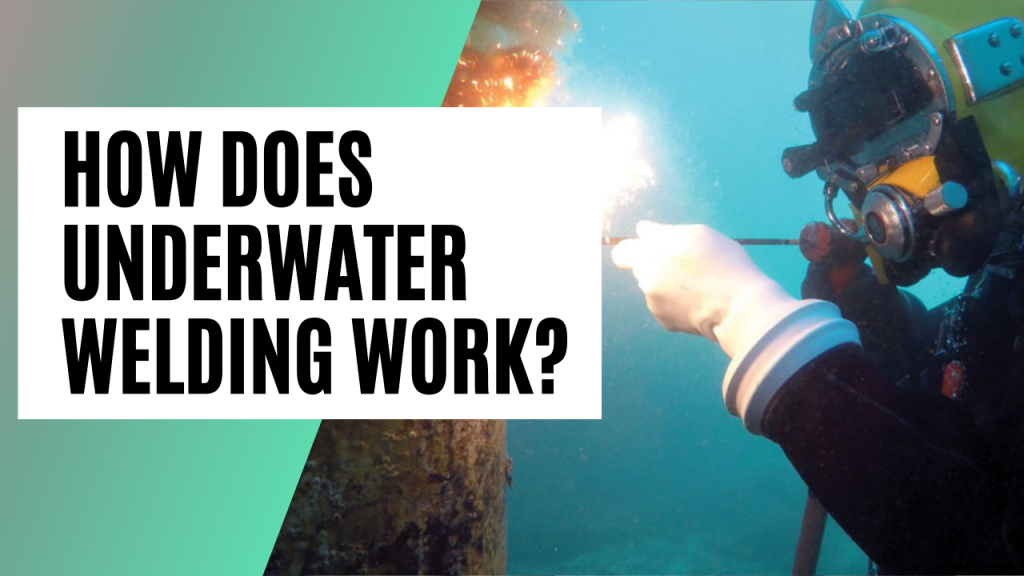

Only a few people know about underwater welding. The underwater welding process surprises many as electricity and water appear to be a dangerous and incompatible combination.

However, underwater welding is a lucrative area and one of the highest paying activities for commercial divers. Underwater welding, also called overpressure welding, was invented in the early 1930s and is still used to maintain and repair fully or partially submerged ship structures.

Inland hyperbaric welders can work on small ocean-going vessels, dams, and bridges. Offshore welders are destined to work on oil rigs, pipelines, and ships. They may even have to do welding work on nuclear power plants.

WHAT IS UNDERWATER WELDING?

Underwater welding, often referred to as positive pressure welding, has been around since the early 1930s and is still used in many parts of the world to maintain and repair marine infrastructure partially or fully submerged in water.

Domestic welders work on bridges, dams, and small craft, while offshore welders work on pipelines, large ships, oil rigs, underwater habitats, and even nuclear power plants.

Welding underwater is actually not much different from welding on dry land. Both use the same basic techniques and equipment, so underwater welders are usually trained as certified above water welders first.

Relevant Read : Best TIG Welder For Aluminum 2023

It is a dangerous field requiring years of training to acquire the required knowledge and skills and the required certification from an accredited commercial driving school.

While mixing electricity and water is one of the threats to the job, surprisingly not the biggest (more on the dangers of underwater welding below).

However, many choose this career path because of the excitement and challenges the job brings – not to mention a good payout averaging $ 53,990 per year (or more for offshore welder divers).

TYPES OF UNDERWATER WELDING

While the job usually involves the use of a special welding rod (or electrode) and volatile balloons, there are two main sorts of underwater welding:

DRY WELDING

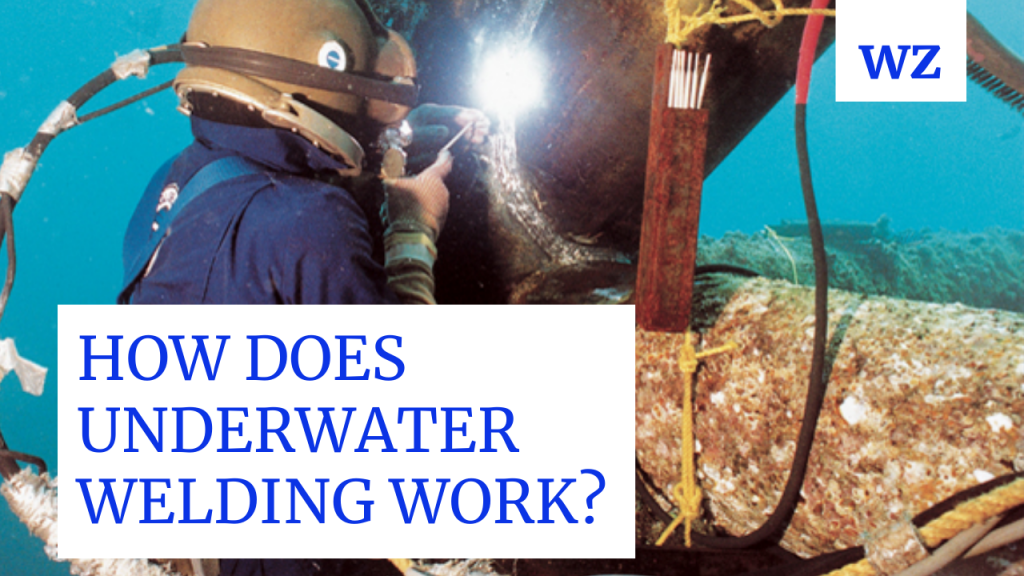

While we usually imagine welding underwater while fully submerged in water, most of it is done in dry habitats. Dry welding uses a dry chamber or living space (overpressure chamber) where water is replaced with a gas mixture to allow one or more welders to do the job in dry conditions.

These rooms can be expensive and are not always available to divers. In this case, welder divers should resort to wet welding where they have nothing to protect them from water.

Relevant Read : BEST WELDING HELMETS FOR MIG

WET WELDING

Wet welding is done depending on the welding area’s convenience and the hardness of the repair required.

One of the reasons it is usually used as a last resort, besides the obvious danger of using electricity in the water, is that the weld is more likely to cool too quickly due to the surrounding water temperature, which increases the chance of cracking.

HOW DOES UNDERWATER WELDING WORK?

Dive welders have a variety of options available to carry out the welding job. Depending on the task being performed, qualified immersion welders and project managers should discuss the most appropriate welding process to meet the requirements.

Here are the different welding methods that can be used.

Relevant Read : BEST BUDGET WELDING HELMETS UNDER $100

WET WELDING

Gas shielded welding, also known as rod welding, is a popular choice for wet welding. It’s versatile and inexpensive.

- With this method, welders create an arc using a consumable electrode powered by the power supply.

- The arc is generated between the electrode and the structure to be welded so that the filler material is melted and deposited on the joint.

- To complete this welding method efficiently and securely, immersion welders must ensure that the electrodes and the base metal surface are clean.

- Before performing the weld, the diver should examine the area for obstructions or other safety hazards.

When everything is ready, the diver-welder signals the team to turn on the power. The power source can generate 300 to 400 amps of direct current. However, triggering the arc requires a certain amount of skill.

Relevant Read: Best welding helmet in 2023

At this point, you may be wondering that the tremendous current that is generated will not electrocute the diver.

- The key to this lies in the layer of gaseous bubbles created when the arc melts the flux. This layer protects the weld and prevents electricity from being conducted outside of itself.

- While these bubbles create an insulating layer to protect the diver from the current, they pose several problems.

- These bubbles obscure the welding area, meaning they reduce the welder’s view.

- These bubbles can also disrupt the weld pool if the diver is not careful.

- For this reason, wet welding presents diving welders with unique challenges.

- Direct current is also used, which is safer than alternating current for underwater applications. Electric welding is definitely one of the most popular options for wet welding.

Often, however, other wet welding methods are also used.

Other common types of underwater wet welding processes are:

Relevant Read: Best auto darkening welding helmet

DRY WELDING

As previously mentioned, dry or habitat welding involves using a hyperbaric chamber concerning the same base welding process.

After creating a seal around the structure to be welded, connected hoses flush away the water and replace it with a mixture of gases such as helium and oxygen.

After all the water has been squeezed out, the hyperbaric chamber is pressurized to the correct depth to prevent decompression sickness.

The technique used depends on the size of the room.

Here are the four types of dry welding methods that welders can choose from:

- PRESSURE WELDING – method of working in a pressure vessel that measures approximately one unit of atmospheric pressure (comparable to pressure at sea level).

- Habitat welding – The welder diver uses a small chamber the size of a chamber with the same outside pressure (ambient pressure) at working depth. The chamber moves the water to the surrounding water before the welder diver enters.

- Dry chamber welding – The welding diver enters the small chamber below and is only covered from head to shoulders (with scuba gear).

- DRY SPOT WELDING – the technique of creating rooms that are bright and about the size of a person’s head. It is placed on the welding site, and the welder diver must insert the electrode into the living space that closes conveniently around him.

- GAS TUNGSTEN ARC WELDING (GTAW) – This welding process is also known as “TIG” and uses a non-consumable electrode made of tungsten. Heat is applied along with an arc to stainless steel, aluminum, and other metals to be welded.

- GAS METAL ARC WELDING (GMAW), also known as “MIG”, is known for its various metal transfer methods. This method uses shielding gas that flows through the welding gun around the electrode to weld non-ferrous metals such as aluminum.

- PLASMA ARC WELDING (PAW) – Also uses an electric arc. The arc is still limited to producing a high arc speed (plasma) and intense heat for welding stainless steel, aluminum, and other metals.

Relevant Read: MIG vs. TIG Welding

SALARY OF UNDER WATER WELDERS

The annual salary for underwater welders ranges from $ 20,000 to over $ 100,000 per year. Welders involved in demanding projects or underwater environments can charge up to $ 300,000 per year.

The salary depends on experience, diving method, and depth. Welders are often assigned per project.

RISK OF SWEAT AND BURNS

Ensuring such underwater welds’ integrity can be more difficult, and there is a risk that errors will go unnoticed. To avoid this, the welder should be properly isolated, and the voltage on the welder should be checked.

Underwater welders also need to consider the safety issues that common divers face. In particular, the risk of decompression sickness due to the increased pressure of inhaled breathing gases.

Relevant Read :Types of Welding

HOW DANGEROUS IS UNDERWATER WELDING?

Because underwater welders have many more variables to work with – varying atmospheric gas, water, and gas pressures, specialized diving, and welding equipment, and limited space, in addition to being supplied with water and electricity – this is a field only for experienced welders divers. (including engineers and managers) willing to avoid risks and deal with hazards such as the following:

- Drowning: Usually caused by Delta P hazards, or differential pressure, when a diver is trapped in a bottleneck due to a large water pressure differential where the water of great force fills another space with great force, sometimes equal to over a thousand pounds of pressure.

- EXPLOSIONS – This can occur when hydrogen and oxygen gases mix and accumulate in pockets.

- Electric shock: Often, the number one concern when dealing with water and electricity, especially when inexperienced welders do not use direct current to supply power.

- DECOMPRESSION SICKNESS – A common underwater diving problem caused by nitrogen bubbles forming in the bloodstream

- HYPOTHERMIA – the result of many hours of daily work in dark and cold water.

Safety precautions include surface mounting, another welder-diver to assist and monitor the primary welders, and communicating with the team during the welding process.

Fortunately, welding programs will equip you for these conditions and more. If you’re looking to start a career in underwater welding, check out our guide on how to become an underwater welder.

Relevant Read : Best Welding Helmets for Beginners

THE FUTURE OF UNDERWATER WELDING

Until sophisticated robots can perform intricate tasks with humans’ dexterity, underwater divers will continue to be a necessity for businesses around the world.

It’s a physically and mentally challenging job, but what causes stress is offset by pride in receiving the technology the world relies on today.

CONCLUSION

While it’s not one of the best careers in terms of working conditions and requirements, it is a great job for those looking to earn a high salary in a short period of time.

Relevant Read :TIG WELDING STAINLESS STEEL

FAQS (Frequently Asked Questions)

What do underwater welders make?

Commercial divers and underwater welders have a mean hourly wage of $26, While the average annual wage is approximately $54,000.

How do underwater welders die?

Suffering electric shock while underwater can be fatal when a diver is trapped in a bottleneck due to a large water pressure differential. The water of great force fills another space with great force, sometimes equal to over a thousand pounds of pressure.

How Dangerous is underwater welding?

One of the dangers of underwater welding is the risk of electric shock to the welder.

To avoid this, the welder must be suitable for a marine environment, properly insulated and the welding current must be controlled.

To avoid this, the welding equipment must be suitable for a marine environment, properly insulated and the welding current must be controlled.

What is the life expectancy of an underwater welder?

We estimate the life span of underwater welders to be 10-15 years. We understand that the low life expectancy of underwater welders affects their service life. The death rate in underwater welding is around 15%, significantly higher than in other professions.