Humankind has welded metal parts together for centuries. Our family members have been sticking metal parts together with welding jigs for thousands of years. However, many different types of welding have been developed since the 19th century, each with its advantages and disadvantages.

Here we look at what means by welding and discuss which types of welding are most suitable for which purpose.

WHAT IS WELDING?

Welding is a manufacturing process where two or more parts are fused using heat, pressure, or both to form a joint while the components cool. Welding is mostly used on metals and thermoplastics, but it can also be used on wood. The completed weld seam can be called a weld seam.

DIFFERENT TYPES OF WELDING

Welding has been used in metallurgy for thousands of years. Forge welding, in which forges connect iron and steel by heating and hammering, was the only feasible technique for some time. It changed in the 19th century when more advanced methods such as arc welding and oxyfuel welding were developed.

Below are some basic welding types and essential types of welding.

MIG Welding

MIG stands for metal inert gas or MIG welding; this process uses a thin wire as an electrode. The wire heats up when it is fed through the welding machine to the welding point. Shielding gas must be used to protect the weld from airborne contamination.

However, it usually takes the form of carbon dioxide, oxygen, argon, or helium. This method is widely used for machining metals such as stainless steel, copper, nickel, carbon steel, aluminum, and more. Of all welding processes, this is the most popular in the construction and automotive industry.

Also, Gas metal arc welding is considered one of the most straightforward welding techniques to learn, making it an excellent focus for beginners. It also requires minimal cleaning, offers fast welding speeds and better control over thinner materials.

If you need an upright quality welding helmet for MIG welding, then you can read our guide about the best welding helmets for MIG in 2024.

Unluckily, some disadvantages associated with this type of welding process are the cost of obtaining shielding gas, as well as the inability to weld thicker metals or perform vertical or overhead welding.

TIG Welding

TIG is one of the best types of welding techniques and is also known as tungsten inert gas or TIG welding. TIG is often used to weld together thin and non-ferrous materials such as aluminum, copper, lead, or nickel. It is widely used in the manufacture of bicycles or airplanes.

In contrast to other types of welding processes, TIG welding uses a non-consumable tungsten electrode to produce the weld seam. It would be best if you still had an external gas supply, usually argon or a mixture of argon and helium.

It is considered one of the most challenging welding methods to master and a technique that produces the highest quality welds.

If you need a quality welding helmet for TIG welding, then you can read our guide about the best TIG welding helmets in 2024.

Since there is only a small area between the arc and place to be welded, a high level of precision and skill is required. Welds resulting from this method are known to be extremely strong.

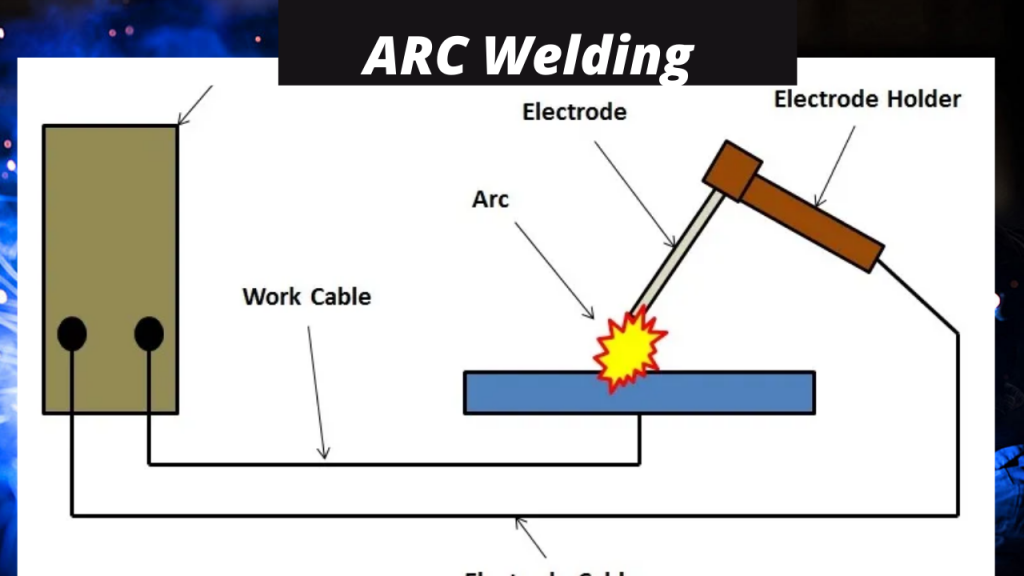

ARC Welding

Arc is one of the types of welding process that includes metal inert gas welding (MIG), electrode welding, tungsten inert gas welding (TIG), also gas tungsten arc welding (GTAW), gas welding, metal active gas welding (MAG), core wire arc welding (FCAW), gas metal arc welding (GMAW) (SAW), protective metal arc welding (SMAW) and plasma welding.

Moreover, these techniques typically use filler material and are mainly used to join metals such as stainless steel, aluminum, nickel and copper alloys, cobalt, and titanium. Arc welding processes are widely used in industries such as oil and gas, energy, aerospace, automotive, and more.

If you need a good quality welding helmet for this, then you can read our guide about the best welding helmets in 2024.

FCAW Welding

As with MIG welding, arc welding also has a continuous wire feed that rotates. There are two separate processes associated with arc welding core wires.

One involves the use of shielding gas, while the other relies on self-shielding agents created when flux breaks down within the wire. This type of welding is known to be cheap and easy to learn. Like the MIG welding process, it is an excellent way for novice welders to start their careers in the field.

If you need a budget welding helmet for FCAW welding, then you can read our guide about the Best Budget Welding Helmets Under $100 in 2024.

Nonetheless, it also allows welders to do their job outdoors (windy conditions do not affect the weld). The semi-automatic arc offers high welding speed and portability, making it a popular technique for construction projects.

Electron Beam Welding

The fusion bonding process uses a beam of fast electrons to bond materials. The kinetic energy of the electrons is converted to heat when they hit the workpieces, melting the materials together.

Electron beam welding (EBW) is performed in a vacuum (using a vacuum chamber) to prevent the laser beam from breaking.

If you need an excellent welding helmet for electron beam welding, then you can read our guide about the Best Welding Helmets for Beginners in 2024.

Moreover, there are many shared applications for EBW that can be used to join thick profiles. It means it can be used in some industries, from aerospace to nuclear and automotive to rail.

Laser Welding

This process is used to join thermoplastics or pieces of metal and uses a laser to deliver concentrated heat, ideal for wheelbarrows, deep welds, and fast joining speeds.

Furthermore, the high welding speed at which this process can be performed is easy to automate and perfect for high volume applications, for example, in the automotive industry. Laser beam welding can be done in the air and not in a vacuum-like electron beam connection.

Plasma Arc Welding

Equally important, Plasma welding is similar to TIG but uses a smaller arc, which improves welding accuracy. Another burner is also used to achieve much higher temperatures. The gas is pressurized in the rod, creating plasma. The plasma is then ionized, making it electrically conductive.

Besides it creating the arc that makes incredibly high temperatures that can melt the base metals, it also allows for plasma welding without filler material, another similarity to TIG welding.

In this way of welding, the welds can penetrate deep into tight welds, resulting in aesthetically pleasing welds and high strength. Also, high welding speeds are possible.

TYPES OF WELDING (FAQs)

What Are The 4 Types of Welding?

Four of the most common types of welding are (MIG) metal inert gas or gas metal welding, arc welding, laser welding, and (TIG) tungsten inert gas welding.

How Does Welding Work?

The welding process by linking two materials together without a separate binder material, unlike brazing and soldering.

How to Weld Metal?

Welding uses an electric current to superheat and melt metal, allowing you to join two pieces of metal together. There are many different ways to weld, but the two most popular ways to weld at home are metal gas arc welding or MIG welding, and arc welding, also called stick welding.

How Does Stick Welding Work?

Also known as manual metal arc welding (MMA or MMAW). Flux-proof arc welding, or rod welding, is a process in which the arc is struck between the metal rods (coated with electrode flux), and the workpiece, shaft, and workpiece surface are fused. form a weld pool.

How Does A Welder Work?

First, a ground wire is connected to the material. Then the welder places an electrode cable against the working material. When the welder pulls the electrode away from the material, it creates an electric arc, also known as the plasma discharge in progress as a result of the electrical failure of the gas.

What Is Welding Used For?

Welding processes are commonly used in a variety of industries including aerospace, automotive, energy, and construction. Used to bond metals, thermoplastics or wood for a variety of applications, it is also used to create works of art by a growing community of artists.

What Is Arc Welding Used For?

Arc welding is a welding process that joins metal to metal using electricity to generate enough heat to melt the metal, and cold-melted metals cause the metals to bond together.

CONCLUSION

Hopefully, by now, you have a basic understanding of the different types of welds. Some classes are machined and require expensive special equipment. Others can be done at home by a hobbyist without breaking the bank. If you’re looking for a welding helmet, be sure to check out one of our guides on comparing the best welding helmet for beginners.