Gas-tungsten arc welding (GTAW), also known as tungsten inert gas or TIG welding, is a joining process for stainless steel.

TIG Welding Stainless Steel involves the use of a tungsten electrode to produce a weld. TIG welding is most commonly used to weld thin stainless-steel profiles.

TIG Welding Stainless Steel gives manufacturers more control over the weld than other welding processes such as gas metal arc welding (GMAW) and protective metal arc welding (SMAW).

The method’s ability to weld at low currents (i.e., an entrance at a lower temperature) and add filler wire, if necessary, makes it ideal for both thin materials and root canals when having thicker plates sections of pipe on one side be welded.

TIG Welding Stainless Steel can be done with or without the use of welding wire (known as autogenous welding) and is, therefore, the method of choice for orbital welding of rigid pipes.

However, argon-rich mixtures with additional helium, hydrogen, or nitrogen are also used to achieve specific results.

In the case of one-sided welding, inert gas shielding is used for the weld seam below the weld seam. This protection prevents oxidation and the loss of corrosion resistance of the stainless steel.

TIG WELDING STAINLESS STEEL: What is Stainless Steel?

Stainless steel is an iron-based alloy that contains varying amounts of chromium. It is the element that gives stainless steel its rust-resistant reputation.

Chromium content can vary between 11% and 30%, with each variation having slightly different chemical properties that affect performance.

Stainless steel is gaining popularity because it is a strong material that can withstand many liquid, gaseous, and chemical corrosion types.

It takes a long time for this substance to become cloudy, and it works well in a wide variety of material applications. Because many kinds of stainless steel can withstand sweltering and cold temperatures, it is a popular material of choice for the pipe and oil industry.

Restaurants, craft breweries, and medical device manufacturers rely on their resistance to bacterial growth, making it a safe food preparation option, medical needs, and transportation of harsh chemicals.

How to Weld Stainless Steel?

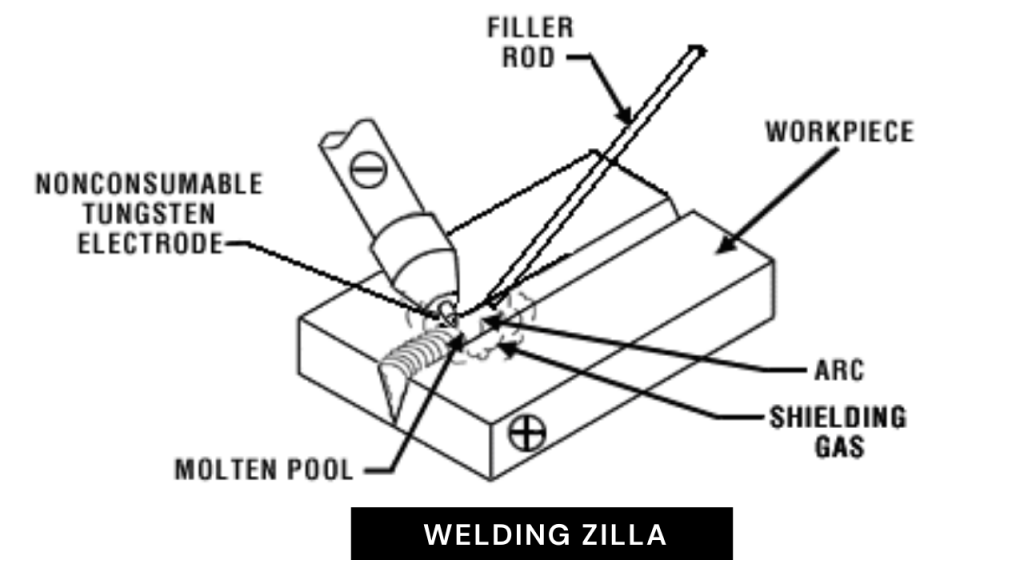

When it comes to TIG welding stainless steel, the energy required to melting the stainless steel is provided in an electric arc.

This arc is created and maintained between the tungsten or tungsten alloy electrode and the stainless-steel workpiece.

Welds made on stainless steel are always performed in direct current electrode negative mode (DCEN) or direct current straight polarity mode (DCSP).

The electrons are hit on the stainless steel workpiece, which improves penetration. The electrode itself is hardly subject to wear. In cases where filler metals are used, this is done in bare rods or, in automatic welding processes, with wound wire.

The inert gas flow protects the arc zone from ambient air, enabling a stable arc to be maintained. Suitable shielding gas is selected based on the materials to be welded.

See our guide about the types of welding.

TIG Welding Stainless Steel Pipe

In TIG welding stainless steel pipe, the filler material’s choice is essential. The choice of filler material is about improving the properties of the weld being produced and meeting the requirements of the final application of the pipe being made.

By choosing low-carbon filler metals, the corrosion resistance of low-carbon stainless steel alloys can be maintained.

Higher carbon filler metals are used in applications that require higher strength, while higher silicon filler metals can increase the weld’s fluidity, increase travel rates, and improve joints.

When choosing filler metals, a filler metal with low trace elements (also called vagrant) is essential. These trace elements include phosphorus, tin, sulfur, arsenic, and antimony, all of which affect corrosion resistance.

In TIG welding of stainless steel pipes, sensitization is the most common cause of corrosion resistance loss.

TIG WELDING STAINLESS STEEL: Is It Difficult?

Stainless steel stores heat very efficiently, which makes welding a little complicated, especially for beginners. With excessive welding heat, stainless steel can warp due to the high temperatures and even warp when it cools.

TIG welding stainless steel can also be very inconsiderate aesthetically as it reveals every stain and scratch that has been left behind.

If you’ve ever welded on a metal table, take precautions before starting as it is so easy to scratch.

Why TIG welding?

The answer is not that simple: it depends on what result you want to get. Stainless steel can be welded using inert gas welding (MIG), gas-tungsten arc welding (TIG), and rod welding. Each of these methods produces slightly different results.

When art comes first, the finesse of TIG welding can go well together. However, when speed and efficiency are paramount, MIG welding may be a better process.

Known for its precision, TIG welding is the ideal technique for projects that require clean, controlled welds, especially with less forgiving materials like stainless steel alloys or aluminum. It is also where it is easiest to prevent distortion.

TIG WELDING STAINLESS STEEL: Does It Rust?

Stainless steel is resistant to all types of corrosion under normal conditions. However, stainless steel can rust in extreme conditions.

Rust happens when the chromium oxide layer – the element that protects stainless steel from rusting – is destroyed or removed. Sometimes this can occur during welding, during the heating or cooling process.

Rust can also be one of the biggest challenges of stainless-steel welding in TIG welding. That’s why it’s so important to clean and prepare your stainless steel before you start.

With a properly cleaned and prepared piece of stainless steel, the chromium oxide interior acts as a protective seal against rust during the welding process. It can help the stainless steel heal from discoloration and permanent stains.

See our guide about the:

Best Welding Helmet for Beginners

Tips for TIG Welding Stainless Steel

One way to avoid warping when welding stainless steel is to clamp a piece of brass or copper behind the weld’s seam. It acts as a cooling mechanism or “heat sink” that absorbs the heat and prevents it from burning. It can also help you to weld the entire seam continuously.

Before TIG welding stainless steel, keep a separate tool kit on hand to prepare and clean stainless steel. Why? Because it is susceptible to a lot of carbon steel.

If one of your tools has carbon steel residue and you come into contact with the stainless steel, those traces will become embedded, and your finished product will rust. Even carbon steel dust can be a rust hazard to stainless steel and should be kept in separate work areas.

The advantages of TIG Welding Stainless Steel

Using TIG welding stainless steel offers multiple benefits to manufacturers, including:

Conclusion

TIG welding is very popular in stainless steel welding. Its main application is the soldering of stainless steel. The great thing is that it can be used for different implementations on different welding jobs.

Welding stainless steel is known to be a difficult task because it retains heat very well. It can lead to warping of the metal. In addition to other metals such as aluminum, nickel alloys, brass, copper, and chromatolysis, TIG welding is also well suited for stainless steel.