Several years ago, the 8010 welding rod made headlines around the welder’s world. If you are fascinated by welding, you may have discovered several different tools useful in completing various kinds of welds.

Eight thousand ten welding rods are particular welding tools and are specialized for welding specific types of steel.

The purpose of an 8010-welding rod is to work with steel pipes that can undergo vertical down welding and out-of-position welding up to 80 Ksi tensile strength, although the rod can also be used in different welding positions.

What Is An 8010 Welding Rod?

The welding company PhiLARC explains that an 8010-welding rod is a high cellulose electrode that is popular for vertical down welding heavy steel pipe. However, its fast-freezing slag is the reason for the easier management of the weld’s shape and size.

In some welding communities, the term rod refers to a welding electrode used in shielded metal arc welding. As a result, the 8010-welding rod is also called an 8010 welding electrode.

Steel with an 80 designation indicates that it uses high tensile steels of 80 ksi. This steel is exceptionally strong with high corrosion resistance and is easily weldable provided the right equipment and techniques are employed.

This electrode’s main component comprises cellulose, a type of organic material made from paper. Since it has a steady, continuous arc, it allows for deep penetration and a smooth weld puddle.

This makes 8010 rods a suitable choice for steel with high tensile strength. Since these electrodes penetrate deeply, they can be used in many other compounds as well.

Using proper equipment is imperative to producing professional quality welding. Still, you also need to know what you’re working with and what type of weld is being attempted to succeed.

How to use an 8010 welding rod?

Starting by cleaning the intended welding site of any possible contaminants, 8010 welding rod may be used to horizontally down weld and out-of-position weld.

As recommended by the Inweld Corporation, The thicker pipe should be preheated to 300-500 degrees Fahrenheit to achieve the best results.

You should use a drag technique on the initial pass and press firmly against the joint with the electrode while performing the root pass. It is prudent to deposit the second pass as soon as possible after the root pass.

Incorporating the weld pool’s side into the base weld material with a weaving stitching technique will result in a more sturdy weld. Still, the welding electrode diameter must not exceed three times the welding electrode. The whipping procedure is not advised.

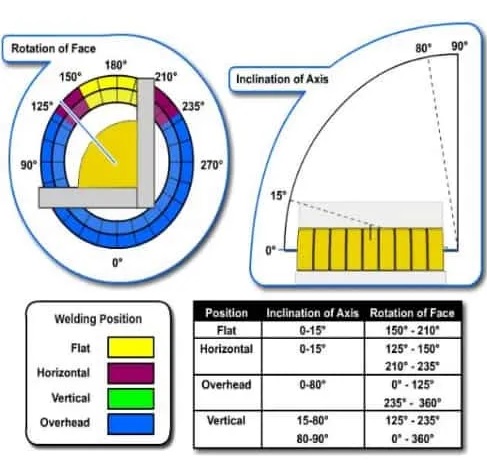

For horizontal welds, tilting the electrode at a 45-degree angle with travel direction is suggested by some welding communities. For vertical welds, hold the rod at a 15-degree angle with the law of travel.

To minimize welding defects such as wagon tracks or worm tracks, the current must be kept high enough when using the 8010 welding rod.

It is more possible for hydrogen that gets trapped in the weld to become a defect if the voltage is too high. Let the weld air cool before attempting to remove the slags.

What Is Vertical Welding?

A vertical weld is noted as a weld placed along a vertical surface or a slight angle of 45 degrees or less in the Steelworker Volume 01 Construction Training Manual. Most vertical welds are placed around pipelines, buildings, and tanks.

Since the force of gravity will pull the molten metal out of the arc as you weld, the vertical weld could be weak and sloppy if you’re not proficient enough or don’t have the correct equipment.

A vertically welding rod needs to take advantage of fast-freeze or fill-freeze electrodes to minimize distortion of the slag caused by gravity and thus better control the shape and size of the weld.

Vertical down welding consists of starting welding on the weld joint’s outer side and progressing downwards into the interior. Vertical up welding involves starting welding at the bottom of the weld joint and moving upwards.

What Is Stick Welding?

A shielded metal arc welder called shield welding is a form of welding where an electrode is used to melt two metal pieces. The electrode reinforces the joints by fusing the alloy both together and adding filler metal to the joints.

Stick welding requires several pieces of equipment:

- Electrode and rod holders often referred to as stingers

- Power supplies with constant voltage

- One of these clamps is used to secure a wall.

- There are welding electrodes and rods available such as the 8010 welding rod described previously.

Various levels of current strength can be used when stick welding. Variation in the current strength directly influences the melting rate, so it is imperative to control current if you seek consistent, high-quality welds.

Using a variety of electrodes for different metal types and varying the penetration rate allows for better welding.

What Is MIG Welding?

Welding guns used in MIG welding use a shielding gas to protect the weld pool and shield it from contamination. MIG refers to the shielding gas, which is usually a blend of argon, helium, or carbon dioxide.

The metal is welded together using a gas metal arc welding (GMAW) or mig welding process; the shielding shields the molten metal from contacting reactive particles in the surrounding atmosphere.

While argon gas is the most common, its welding speed is slower, and the heat is lower—helium gas results in a faster weld (with deeper penetration and higher heat) and greater penetration.

Welding these two metals together can be done with MIG welding as long as the materials have a similar melting point. You need to have:

- Power supplies with constant voltage

- There are three kinds of wire feeders: add-on wire feeders, suitcase wire feeders, and spool feeders.

- This gun is called a MIG gun.

- There are two types of gas regulators.

- An earth clamp and hoses are required.

There are many types of wire feeders, chosen based on what welding you intend to do and how much welding.

Wire feeders that add more wire are beneficial for specialty jobs like those found in shops and factories that need to weld extensive parts. Suitcase welders can be used for one-off projects or short-run jobs.

These are soldered onto certain kinds of MIG guns, ideal for aluminum welding since the wire crosses such a short distance.

Besides, MIG equipment offers advantages such as fast welding speeds and the ability to use it for various welding positions.

According to Gene Mathers, MIG welding is one of the most commonly used manual arc welding processes for aluminum in his book The Welding of Aluminum and Its Alloys.

What Is TIG Welding?

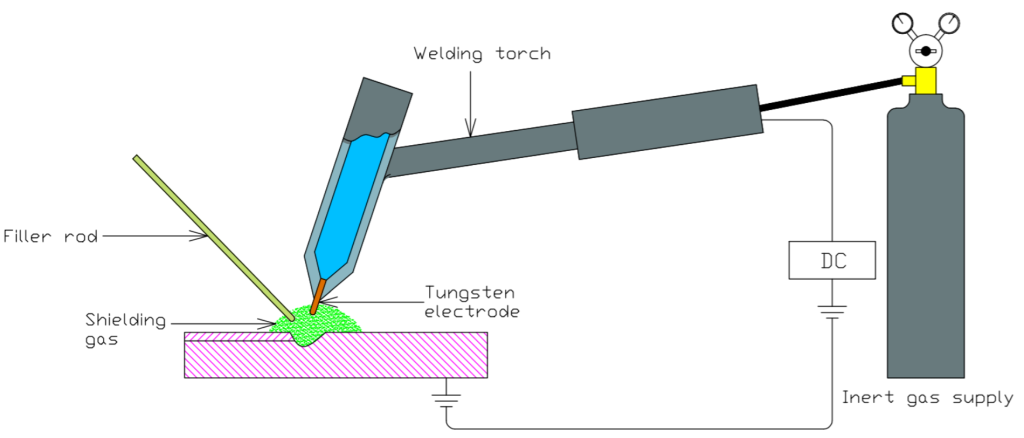

TIG welding involves melting the base metal with an electrode made of tungsten. The electrode in TIG welding is non-consumable, while the weld is protected with a shielding gas, typically argon.

A TIG welding machine uses a torch that heats the metal so that it forms the weld. The temperature is gradually increased while working so that it doesn’t start or stop causing the weld to crack.

For TIG welding, specific equipment is required that is different from those needed for stick welding and MIG welding. It includes:

- This electrode is made of tungsten.

- a TIG welding machine with constant current (preferably a device tailored to TIG welding)

- It can be used to hold a torch or electrodes

- An apparatus for supplying shielding gas.

- This metal rod serves as a filler.

Depending on the composite materials of the tungsten electrode used, the electrode can vary. The tungsten electrodes are usually the cheapest but tend to be contaminated more easily and don’t have as good conduction as other electrodes.

Thoria particles are commonly added to the tungsten to increase conductivity and minimize contamination. A zirconia core can sometimes be combined with the tungsten to increase conductivity further, decrease contamination risks, and lower cost.

What Is the Advantage and Disadvantage of Stick Welding as Compared to MIG and TIG Welding

Generally speaking, stick welding is considered a more flexible method of welding than MIG and TIG because clean, contaminate-free metal is required to weld, while MIG and TIG require additional time to remove any paint or corrosion before proceeding.

Welding with MIG and TIG tends to look nicer, with less splatter and a smoother seam finish, but MIG and TIG welding require more preparation. MIG and TIG welding is also more apt to work with thin metals.

MIG welding does not pause work to replace an electrode used up. Stick welding sometimes burns through thin metals and is ideal for thick, high-tensile strength materials.

There are several advantages to stick welding, including:

- The welding site does not need to be cleaned of paint or rust.

- Different electrode materials can be used when welding different metal types

- In this case, the wind plays no role.

- The grounding clamp can be positioned away from the welding point and still works well

- It is much cheaper than TIG welding, especially for thicker metals.

Unlike MIG and TIG welding, stick welding has some drawbacks:

- Before painting or additional welding, the slag needs to be chipped away.

- Thinner metals can be burned by it.

- More splatter occurs during MIG welding than during TIG welding.

- A pause in welding is required to replace consumable electrodes.

- MIG and TIG welding make uniform, smooth, and clean welds, whereas fusion welding does not.

You will find that one welding process or another may be better suited to the object you want to weld, and that depends on how much welding you intend to do. Welding with a stick system may be adequate for you, but if you’re most concerned with welding thin metals or want the best possible weld, you might benefit from a TIG or MIG system.

Related Posts:

- Best Stick Welders (Arc Welders) – Top Picks and Reviews

- Top 10 Best TIG Welders For the Money Reviews…

- Types of Welding (): What are they used for, and…

- Welding Sunburn – Can Welding Really cause sunburn?…

- MIG vs. TIG Welding: How to choose between MIG and…

- How to Weld Exhaust Pipe with Stick ,Flux , MIG and…