It’s not illegal to weld on a truck (vehicle) as long as it’s a passenger-carrying vehicle and even then, commercial vehicles can have welding repairs made as long as they follow the manufacturer’s instructions. Don’t start welding on your truck if you’re new to welding.

Is It Legal To Weld A Truck Frame? As the skeleton of a vehicle, the frame, also known as the chassis, becomes increasingly visible as the vehicle ages.

A car’s undercarriage keeps it strong enough to do its job. It may seem like the best solution to weld the chassis, but the legal waters can be murky in some areas.

Federal law does not make it illegal for a vehicle’s frame or chassis to be welded. Although they do state that welding repairs should be performed in accordance with the manufacturer’s instructions.

Legal advice is always recommended before undergoing any irreversible modifications or repairs, as local laws can be trickier.

When it comes to welding the chassis/frame, the US government tends to be relatively liberal compared to some other nations. Here you can find information about welding frames.

In the rare and unlikely event that a donor car is listed on the VIN registry as stolen or destroyed, welding the frame will not be an issue. They are called “cut-and-shuts“.

What’s a Cut and Shut?

It is a car that has been engineered by using two or more cars and welding the parts together to make one car. To perform a cut and shut, you need at least two cars, each of which has been wrecked at one end.

Both cars will be cut in half by a welder, and the parts that were not impacted will be salvaged.

Although a welder attends to this vehicle, it is still highly dangerous. Due to the fact that frames that have been vertically cut by a welder and then welded back together won’t be able to resist the force needed during a high-speed collision.

Accidents involving cuts and shuts typically lead to a lot more injuries than those without. Check all the VIN points on the vehicle to test for a cut and shut. There’s nothing wrong with asking questions if none of them match.

What’s the Best Type of Weld for Truck Frames?

Most people tend to use one of the two major types of welding in auto work, frame or body, in general. A MIG welder and a Tig welder are the two types. There are similarities between the two arc welding processes, but they’re different in many ways.

TIG (Tungsten Inert Gas) – This method of welding is used to directly bond two metals. For something like a truck frame, it would be less recommended.

In general, smaller metal pieces are more suitable for TIG welding than larger ones. Having no consumable filler is an advantage, but you will need one if you’re welding a truck frame.

The Metal Inert Gas (MIG) – welding method tends to be easy to use, easier to correct, and better for bigger welds. In wire welders, the wire filler is fed into the weld in order to create a weld between two metal pieces.

MIG is definitely an ideal choice over TIG when it comes to welding your truck’s frame. MIG auto-repairs are popular with more experienced welders due to their ability to work with thicker welds and their ability to fix minor errors effortlessly.

Who Is the FMCSA?

Among the government bodies that set rules regarding vehicular safety is the Federal Motor Carrier Safety Administration (FMCSA). There are a number of rules regarding frame welding in the 393.201 rule, which can be viewed through the link above.

Here’s a summary of them below:

- Despite its high weight, commercial motor vehicles are not permitted to be cracked, sagging, loose, or broken.

- Neither the cab nor the body of the vehicle may be loose, broken, or missing their bolts or brackets.

- If the manufacturer specifies otherwise, the frame rail flanges should not be bent, cut, or notched.

- Commercial motor vehicles have to be welded to their frames or chassis in accordance with the manufacturer’s recommendations.

- It is also essential to follow the manufacturer’s recommendation when welding the frame back together.

- There shall be no holes drilled in the top or bottom rail flanges, unless the manufacturer specifies otherwise.

- It is actually the federal government that makes the rules. When passengers are not followed, they can be seized, and businesses handling passengers can face fines that, if not paid, can result in enforcement action.

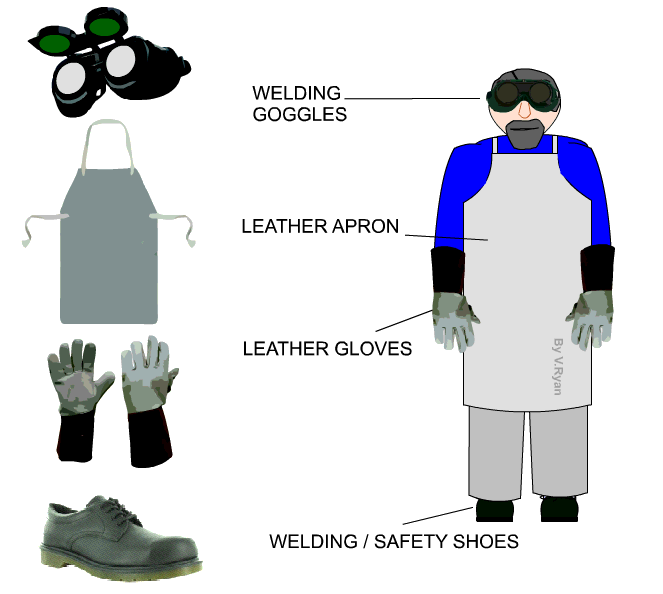

What Equipment Will I Need for Auto Welding?

It’s likely that if you’re reading this post, you’re considering welding your truck frame. You won’t invalidate your car’s eligibility to be on public roads if you’re not welding a commercial truck.

Whether you’re new to welding or just starting out and want to make sure you’re prepared to handle whatever welding tasks you need to, take a look at our list below:

An Angle Grinder – It is impossible to keep weld sites clean and flush with just your hand pressure, so a grinder will help you get rid of excess fillers and keep your weld sites as clean and flush as possible.

Pneumatic Saw – When welding, it’s important to line up your fits. Making fine welds on the frame is easier with a pneumatic saw since it’s much more precise.

Aviation Snips – It will occasionally be necessary to cut sheet metal patches, and the simplest way to do this is with aviation snips.

Cold rolled steel and stainless steel can be cut at 18 gauge and 23 gauge, respectively. Several welding disciplines can benefit from this.

Welding Clamps – Among clamps, welding clamps with locking mechanisms is the best option. Metal is held in place while welding with them. When you’re welding below, they’re especially helpful.

Dolly Set – A dolly set and hammer will be helpful in shaping sheet metal when you have to shape bodywork.

Body Hammers – Unless an improper type of hammer is used, hammers are the best tool for bodywork.

Sheet Metal Gauge – Welders who use MIG welding are extra likely to benefit from knowing how to gauge their sheet metal. Due to being able to determine thickness, a more accurate MIG setting can be achieved.

Safety Equipment

When you are exposed to extreme heat, it is more important than ever to keep your safety first. Be sure to purchase a welding helmet and a welding coat in addition to welding gloves. Some people may overlook simple precautions, but that’s what makes horror stories at campfires.

How Can I Practice Welding When Starting Out?

Practicing welding can seem daunting when you’re just starting out. It won’t make sense to practice on your car since you know that’s a bad idea, so how are you going to acquire the skills necessary to handle a truck with confidence?

To begin, we recommend enrolling in a community college course at your local college. If you have a certification, it will help you get a job, and if you’re not self-motivated, it’ll help you learn.

You can start your self-starting journey by reading books or watching YouTube videos if you are not sure where to start. You’ll learn much quicker when you begin practicing if you learn the basics and fundamentals from books and videos first.

You’ll want to go to the scrapyard if you’ve been doing either of the above for a long time, but you need to practice now. A scrap yard has cheap materials that you can use to practice welding, but welding metal is still necessary.

Beginners should start from the basics and learn welding from the bottom up. You will want to practice breaking each weld you make when you start practicing so you will be more likely to correct mistakes and replace welds.

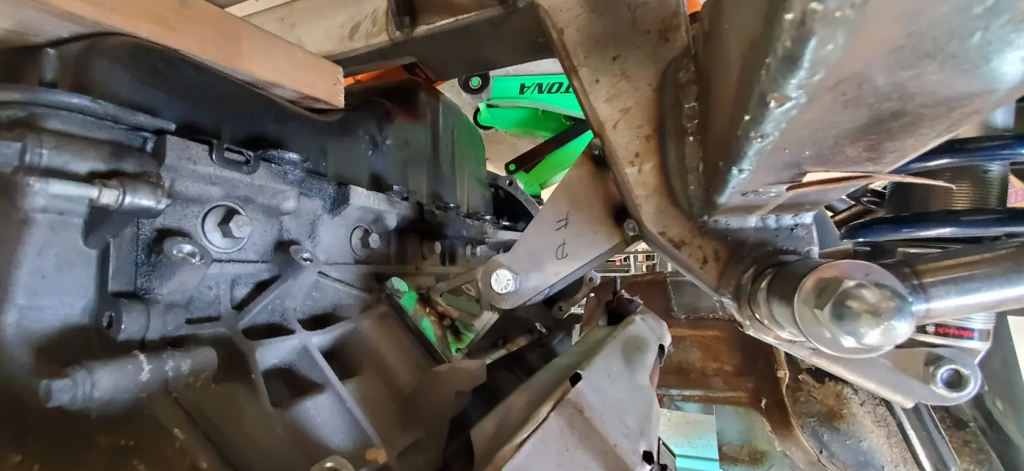

Does Welding a Vehicle or a Truck Frame Weaken It? Is It Safe?

We live in buildings where the foundations require welding, and in many cases, frames, as do most vehicles, planes, and trains. There is some debate as to the general strength of welding frames, particularly once such frames have been broken.

A welded frame is weaker because of welding? You may hear that welding a frame is detrimental to it, especially when it comes to vehicles.

In addition, there are those who will tell you that welding a frame will strengthen the foundation, but it ultimately depends on the type of weld.

Many welding methods exist, but some produce stronger bonds than others, according to the type of metal and substrate used in the welding process.

The advantages and disadvantages of each welding technique differ from the others. They each have a unique style and are very good at what they do.

Is It Safe to Weld a Truck Frame?

Some things may be wrong with your older truck if it is an older model.

For the right cost, most items that malfunction usually have something to do with the undercarriage.

On the other hand, if a crack appears in the body of the truck, there is no straightforward way to fix the issue.

Is it safe to weld a truck frame?

No, welding a truck frame is not safe. Although experienced shops and welders can often repair a crack in a truck frame effectively, an inexperienced welder will likely be unable to do so satisfactorily, making the frame considerably weaker as a result.

A cracked and rusted truck frame can be welded to make it look good, but that does not necessarily mean that the frame is safe to support the truck’s weight.

Because trucks may have high speeds, may ride over bumps, and may be involved in accidents, an unsturdier frame could have disastrous consequences. Welders are not to be trusted.

Common Problems in Truck Frames

Truck frames are prone to a few issues that are commonly brought about by fatigue, stress, or poor workmanship.

Bending

The term “bending” refers to the permanent change in the shape of the frame. A load dropping onto a cargo body or loading too much cargo on the cargo body can cause bending. The frames of cars involved in accidents often bend.

Cracking

Fatigue, high-stress levels, and poor workmanship can sometimes cause frames to crack. When a crack appears between axles, it usually starts at the bottom of the flange and then extends upwards through the web.

Auto body shops can repair bent and cracked frames, but the repairs are usually costly, and insurance companies often opt to total the truck rather than spend the money and time on repairing the frame.

Additionally, many users have found that even if a frame has been repaired correctly, the performance and handling of the vehicle are never the same, with noticeable differences noted by drivers.

Because of this, many truck owners are often recommended to simply scrap their truck out for parts, rather than attempting to repair it.

Challenges of Welding Truck Frames

You may think that welding a cracked truck frame is a simple and straightforward way to fix your frame problems. However, there is much more to this process than you might think.

Welding truck frames can be unsafe due to the following reasons:

There is a risk of safety due to the lack of penetration. Solid metal should be used to construct truck frames. Welding is prone to having problems when completed by beginners, as most welds join only the surface of the bases. In the case of significant stress on the frame, this is of little benefit.

There is not enough control among most welders. It is essential to place a high priority on control when welding a truck frame. As well as on behalf of the welder, this is important to support the frame throughout the welding procedure.

Therefore, truck frame welding can only be done under the most controlled conditions at the original manufacturing plant.

What to Do When Welding a Truck Frame

However, there will still be some who attempt to weld their cracked truck frames, even with all the evidence that welding truck frames, especially those undertaken by amateurs, is not safe. Consider the following steps if this is the case:

You shouldn’t build a rigid frame and then a flexible one. Whenever the frame’s constitution changes suddenly, weakness will be amplified. In order to determine if the welded frame can support the truck’s payload, use the lower yield for calculations.

The reinforcements should extend at least twice the frame height beyond the weld before starting the taper. As a result, the safety net and reinforcements are maximized.

Steel that is denser is more potent than steel that is thinner. If you are welding a truck frame, make sure not to skimp on materials.

Prepare for the weld as thoroughly as you can. Make sure you thoroughly examine all designs and have a plan of attack in place regarding what the final frame should look like, what welding process you plan to use, and how you would proceed in the event that an issue was to arise.

Before starting the welding process, practice the process you will use on the frame of the truck.

If you are still unsure whether you can weld the frame in an actual situation, do not attempt it until you are confident in your welding process and have experience performing welds in real situations.

Concerns when Driving on a Welded Frame

Fixing a crack in a cracked truck frame may seem like a good idea, and it may even be considered “successful.” However, there are a few things to keep in mind before you start driving the vehicle.

Legality

On some public highways, cars with welds in their frames are simply illegal to drive. “Holes shall not be drilled into the top or bottom of rail flanges, except as authorized by the manufacturer,” according to Title 49 of the Federal Motor Carrier Safety Administration (FMCSA).

The FMCSA code prohibits the use of vehicles with frames that have been cut, welded, drilled, modified, or repaired in any other way, so many vehicles with such structures may be illegal for use on public roads and restricted to private, off-road purposes.

You may be subject to some severe penalties if you drive a vehicle on a highway with a poorly-welded frame.

Liability

After an accident involving an aftermarket frame weld, the person that welded it might be liable in civil court if the accident was caused by the weld.

A welded frame, in addition, can make the process of getting insurance more complicated in the event of an accident.

Are There Other Ways to Repair a Damaged Frame?

The majority of times, when a frame cracks a vehicle is unsalvageable because either a vehicle has been seriously damaged or the frame has rusted and degraded enough to cause issues more than once.

Those in the field claim that fixing cracks in the frame of a truck with a brace that uses a bolt to secure the flawed portion is more effective.

Like welding, the bracing system on a compromised frame provides dubious reinforcement, and only a professional should attempt it.

Overall, when considering welding a truck frame, the following principles need to be considered:

It is only worthwhile to consider frame repair for vehicles that are new enough to maintain a value greater than that of the frame. A quality frame repair costs around $10,000.

Truck frame welds ought to be performed by professionals with extensive experience.

Ensure you know how to drive a vehicle with a repaired frame in your state.

What Is the Cost to Weld a Truck Frame?

An accident or poor workmanship could damage your truck’s frame. Fatigue, stress, and poor workmanship are all possible causes.

The cost of welding your car’s frame is sometimes lower than that of replacing it, but this is often not the best strategy.

A corroded truck frame is one of the potential hazards and hazards to you and other drivers on the road, according to most professional welders.

You should seriously consider scrapping your vehicle if its frame has been bent or cracked. Truck weight and uneven surfaces, as well as much heavier loading, may cause welds to become weak points.

How much does a welding truck frame cost?

Depending on how severe the damage is, welding your truck framework may cost you up to 10,000 dollars.

In the U.S., Payscale reports an average welder’s rate at $18,27 per hour. However, prices vary according to the job, welding style, and the material.

Are You Allowed To Weld Subframes?

A corroded subframe shouldn’t be welded to the mounts for the lower suspension arms because this would decrease the strength of the structure.

Subframes fall into the category of high-stress components, so repairs and welds may not restore the frame’s original strength.

It may be possible for a coded welder to repair a subframe in such a way as to pass inspection, however, such an operation will be costly.

If corrosion has caused a hole or a split in highly stressed components, such as the subframe, these components should not be repaired. Using this method might put one’s own safety and the safety of others at risk.

The severity of the damage to your subframe could make repairing such a vital part of your automobile a risk.

Will Welding On A Vehicle Damage Electronics?

Can welding damage the electronics on a vehicle? The short answer is yes; welding can damage your electronics if your welder does not take the necessary precautions. The results of welding on vehicles and the subsequent damage to electronics are, however, widely conflicting.

The design decisions made by contemporary car manufacturers make it impossible to conduct welding on an automobile without causing electronic damage.

Before beginning any repairs that affect electrics such as welding, consult your owner’s manual and the manufacturer of your vehicle. Once that’s done, make sure you:

- To open the electrical circuits to your vehicle battery, always disconnect the negative battery terminal from the vehicle. The overvoltage risk is thus reduced by disconnection.

- Make the welding ground clamp as close as [possible to your welding arc to reduce the electrical path between your welding arc and the ground

- Under the hood, disconnect the airbag plugs

This may result in disruption of the OBD2 system, so disabling your vehicle’s ECU bus is not recommended.

Should I Disconnect The Car Battery When Welding?

When welding on your vehicle, make sure the negative battery is disconnected. Negative terminals are disconnected, and when they are both connected to the same voltage, the loop is broken, preventing damage from overvoltage.

Damage to electrical circuits may occur as a result of electrical current. In addition, make sure that all electronic components, modules, batteries, and sensors are removed from the welding area.

How Do I Check For Frame Damage?

Inspect your vehicle for frame damage after you buy a second-hand car or when purchasing a used car. Look for these five signs:

- Damage or bending that is clearly visible. See if your car has wrinkles, cracks, or corrosion around and under it

- There is a problem with the alignment of your vehicle. You may have a damaged frame if you see your car pulling in one direction despite having the wheels aligned

- A strange noise has been heard. Strange creaking or squeaking sounds can be produced by frame damage in different areas of your vehicle

- Shocks or suspension wear unevenly. In the event of frame damage, your vehicle’s weight will be unevenly distributed, which will result in uneven tire wear.

There is a problem with the fit of other parts. When you damage a car’s frame, additional components may not align properly, including doors, windows, and mounts

How Do You Protect Your Gas Tank When Welding A Truck Frame?

Gas tanks that are empty contain fumes and oxygen, which are highly flammable.

Any time you are welding around a flammable source, you should always exercise extreme caution. In order to properly drain the tank, it is best to run the exhaust pipe off the exhaust.

After allowing the exhaust fumes to purge the tank for 20 minutes, cover it with plastic to keep the plastic from being exposed to air. Unless you wish to disclose any exposed pipes or have leaks, removing the tank is the best option.